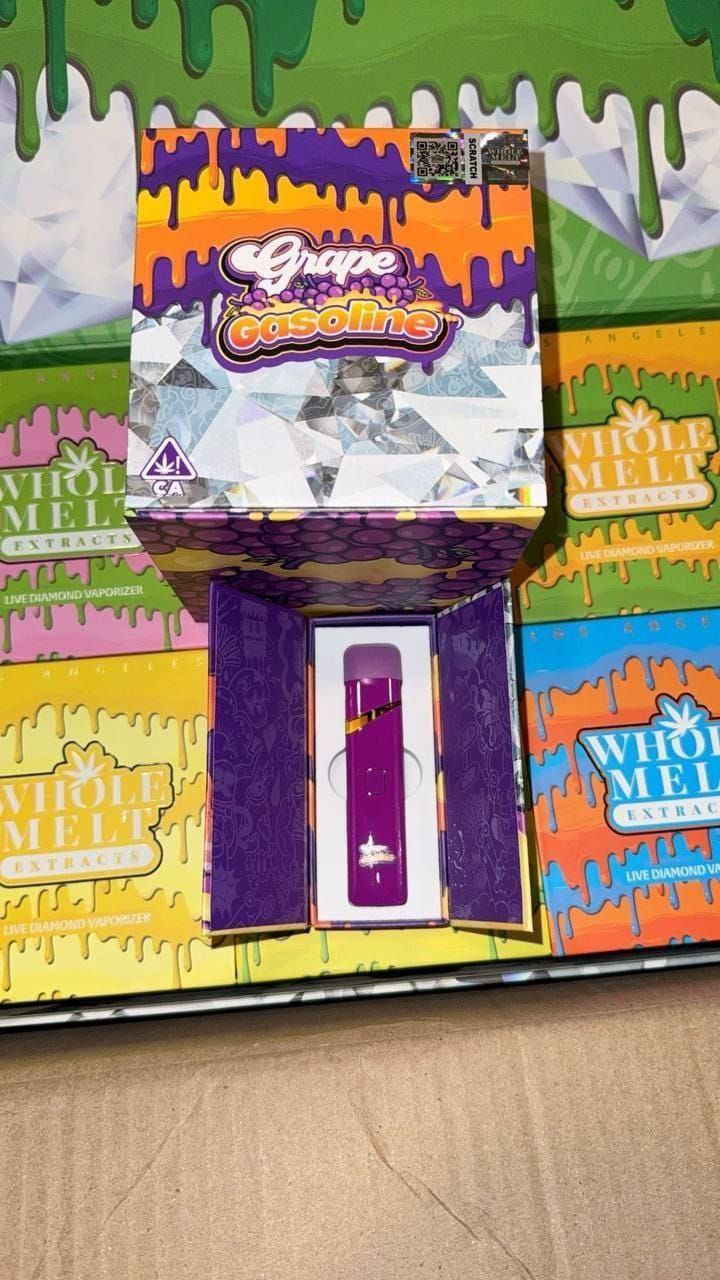

Whole melt extracts are a popular choice for vape disposables due to their high potency and flavorful profile. This type of extract is made using a process that involves freezing fresh cannabis buds and then extracting the trichomes to create a concentrated product that is rich in cannabinoids and terpenes.

Harvesting and Freezing Fresh Cannabis Buds

The first step in the extraction process is to harvest fresh cannabis buds at peak ripeness. Once the buds are collected, they are immediately frozen to preserve their trichomes and terpenes. Freezing the buds helps to prevent any degradation of the cannabinoids and ensures a high-quality product.

Extraction Methods for Whole Melt Extracts

After the buds have been frozen, they are then processed using a variety of methods such as cold water extraction, dry sift, or ice wax extraction. These methods involve sifting or washing the frozen buds to separate the trichomes from the plant material. The resulting product is a fine powder or resin that is rich in cannabinoids and terpenes.

Drying and Curing the Extract

Once the trichomes have been extracted, they are then dried and cured to remove any excess moisture and to enhance the flavor profile of the extract. This drying and curing process can take anywhere from a few days to a few weeks, depending on the desired consistency and flavor of the extract.

Packaging and Consumption

After the drying and curing process is complete, the whole melt extract is then packaged into vape disposables for easy consumption. These disposables are typically filled with a measured amount of whole melt extract, allowing for easy and convenient use on the go.

Benefits and Precautions of Whole Melt Extracts

Whole melt extracts are known for their high potency and flavorful profile, making them a popular choice for cannabis enthusiasts looking for a strong and enjoyable vaping experience. The extraction process used to create whole melt extracts ensures a high-quality product that is rich in cannabinoids and terpenes, providing users with a potent and flavorful vaping experience.

Tips for First-Time Users

For first-time users of whole melt disposables , it is important to start with a low dose and gradually increase as needed. This will allow you to gauge your tolerance and find the right dosage for your needs. Additionally, be sure to store your disposables in a cool, dark place to preserve the potency and flavor of the extract.

Conclusion

Overall, exploring the extraction process of whole melt extracts for disposables provides valuable insight into the production of these high-quality products . By understanding how whole melt extracts are made, you can better appreciate the craftsmanship and care that goes into creating these potent and flavorful vaping options. So, next time you reach for a whole melt disposable, you can vape with confidence knowing that you are enjoying a premium product that has been carefully crafted to deliver a top-notch vaping experience.

SBSA Technology's EDI Cloud Services: The Key to Unlocking Your Business Potential

October 18, 2024 22:30 - no comments yetIn today's fast-paced business world, Electronic Data Interchange (EDI) has become an essential tool for companies to streamline their operations and improve communication with trading partners. However, traditional EDI solutions can be costly, complex, and time-consuming to implement and maintain. This is where EDI cloud services come in, offering a scalable, flexible, and cost-effective solution for businesses of all sizes. SBSA Technology's EDI cloud services are designed to help businesses unlock their full potential by providing a secure, reliable, and efficient way to exchange electronic data with trading partners.

Benefits of EDI Cloud Services

SBSA Technology's EDI cloud services offer a range of benefits for businesses, including reduced costs, increased efficiency, and improved scalability. By outsourcing EDI operations to the cloud, businesses can eliminate the need for expensive hardware and software, reducing capital expenditures and minimizing the risk of obsolescence. Additionally, EDI cloud services provide a scalable solution that can grow with the business, allowing companies to quickly adapt to changing market conditions and trading partner requirements. With SBSA Technology's EDI cloud services, businesses can also improve their overall efficiency, automating EDI processes and reducing the risk of errors and discrepancies.

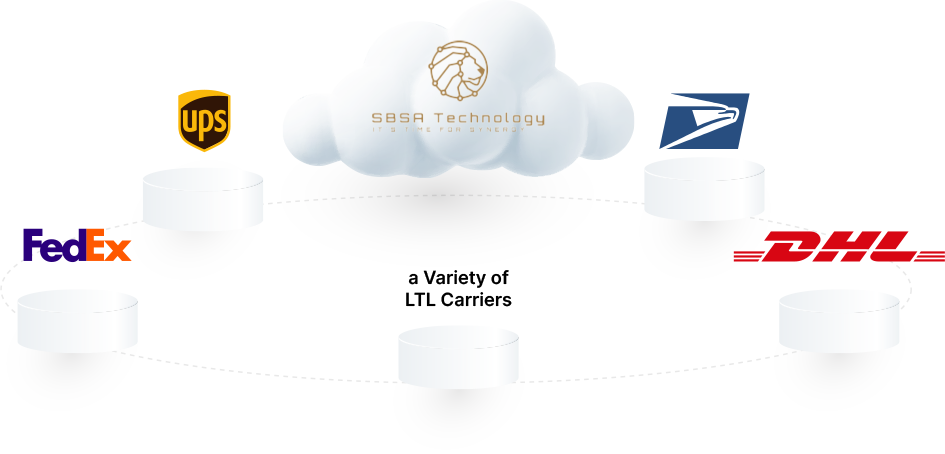

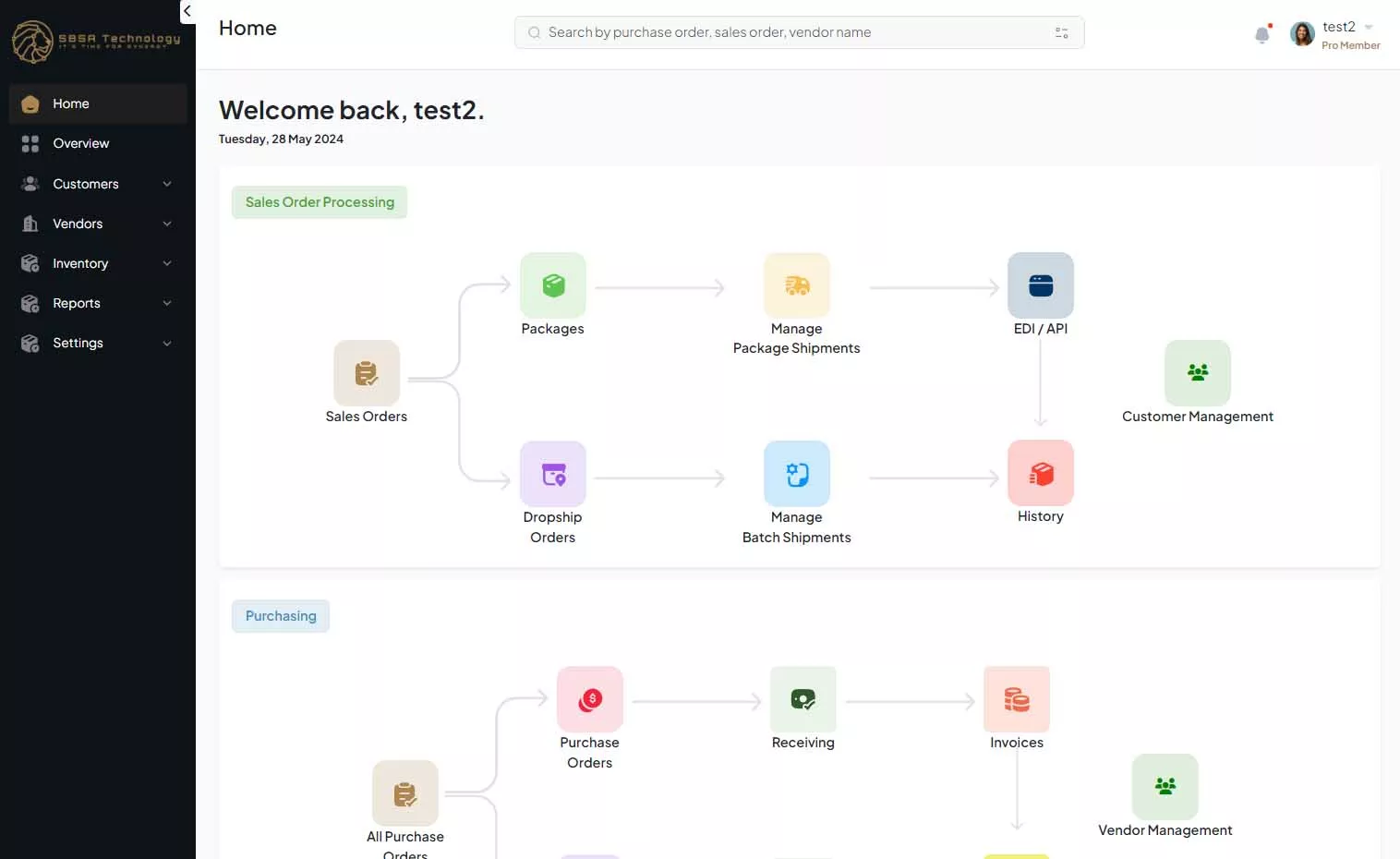

How EDI Cloud Services Work

SBSA Technology's EDI cloud services are designed to be easy to use and implement, with a simple and intuitive interface that allows businesses to quickly and easily exchange electronic data with trading partners. The company's EDI cloud platform provides a secure and reliable connection to a network of trading partners, allowing businesses to send and receive EDI documents in real-time. SBSA Technology's EDI cloud services also include advanced features such as data mapping, data translation, and data validation, ensuring that EDI documents are accurate and compliant with trading partner requirements.

Security and Compliance

SBSA Technology's EDI cloud services are designed to provide a secure and compliant solution for businesses, with advanced security measures in place to protect sensitive data and prevent unauthorized access. The company's EDI cloud platform is fully compliant with all major EDI standards and regulations, including ANSI X12, EDIFACT, and XML. Additionally, SBSA Technology's EDI cloud services are audited regularly to ensure compliance with industry standards and best practices, providing businesses with peace of mind and minimizing the risk of non-compliance.

Case Study: Unlocking Business Potential with EDI Cloud Services

One company that has benefited from SBSA Technology's EDI cloud services is a leading manufacturer of consumer goods. The company was struggling to manage its EDI operations in-house, with a complex and costly system that was prone to errors and discrepancies. By outsourcing its EDI operations to SBSA Technology's EDI cloud services, the company was able to reduce its costs, improve its efficiency, and increase its scalability. With SBSA Technology's EDI cloud services, the company was able to automate its EDI processes, reducing the risk of errors and discrepancies and improving its overall supply chain management.

Getting Started with EDI Cloud Services

Getting started with SBSA Technology's EDI cloud services is easy, with a simple and straightforward implementation process that can be completed in a matter of weeks. The company's team of EDI experts will work closely with the business to understand its EDI requirements and develop a customized solution that meets its unique needs. With SBSA Technology's EDI cloud services, businesses can quickly and easily exchange electronic data with trading partners, improving their overall efficiency, reducing costs, and increasing scalability.

Conclusion

In conclusion, SBSA Technology's EDI cloud services offer a scalable, flexible, and cost-effective solution for businesses of all sizes. With a range of benefits, including reduced costs, increased efficiency, and improved scalability, EDI cloud services can help businesses unlock their full potential and improve their overall supply chain management. By outsourcing EDI operations to the cloud, businesses can eliminate the need for expensive hardware and software, reduce the risk of errors and discrepancies, and improve their overall efficiency. With SBSA Technology's EDI cloud services, businesses can rest assured that their EDI needs are in good hands, allowing them to focus on their core operations and drive growth

Common Challenges in Silicon Steel Processing and Solutions

October 15, 2024 10:21 - no comments yetprecision slitting line, also known as electrical steel, is a type of steel alloy that contains a small amount of silicon. It is widely used in the production of electrical equipment, such as motors, generators, and transformers, due to its excellent magnetic properties. The processing of silicon steel involves several stages, including hot rolling, cold rolling, and annealing. However, during these processes, various challenges can arise that affect the quality and performance of the final product.

Challenges in Hot Rolling

Hot rolling is the first stage in silicon steel processing, where the steel slab is heated to a high temperature and rolled into a sheet. One of the common challenges in hot rolling is the formation of surface defects such as cracks and scratches. These defects can be caused by improper temperature control, inadequate lubrication, or worn-out rolls. To overcome this challenge, manufacturers can implement advanced temperature control systems and use high-quality lubricants to reduce friction between the rolls and the steel sheet.

Challenges in Cold Rolling

Cold rolling is the second stage in silicon steel processing, where the hot-rolled sheet is further rolled at room temperature to achieve the desired thickness. One of the major challenges in cold rolling is the formation of internal stresses that can lead to warping or distortion of the sheet. This can be caused by uneven cooling rates or improper tension control during rolling. To address this challenge, manufacturers can use advanced cooling systems that ensure uniform cooling rates and implement tension control systems that maintain consistent tension throughout the rolling process.

Challenges in Annealing

Annealing is a heat treatment process that involves heating the cold-rolled sheet to relieve internal stresses and improve its magnetic properties. One of the common challenges in annealing is achieving uniform heating throughout the sheet. Non-uniform heating can lead to inconsistent magnetic properties and reduced performance of the final product. To overcome this challenge, manufacturers can use advanced heating systems such as induction heating or vacuum annealing furnaces that ensure uniform heating throughout the sheet.

Solutions for Surface Defects

Surface defects such as cracks and scratches can be addressed through various solutions such as grinding or polishing. Grinding involves removing a thin layer from the surface using abrasive materials such as sandpaper or grinding wheels. Polishing involves using finer abrasives to remove minor scratches and achieve a smooth surface finish. Additionally, manufacturers can implement quality control measures such as visual inspection or automated defect detection systems to identify surface defects early on.

Solutions for Internal Stresses

Internal stresses caused by uneven cooling rates or improper tension control during cold rolling can be addressed through stress relief annealing (SRA). SRA involves heating the sheet at a lower temperature than full annealing to relieve internal stresses without affecting its magnetic properties significantly. Another solution is to use advanced materials with improved formability that are less prone to internal stresses.

Solutions for Non-Uniform Heating

Non-uniform heating during annealing can be addressed through advanced furnace designs such as vacuum furnaces or induction furnaces that ensure uniform heating throughout the sheet. Additionally, manufacturers can use thermocouples or infrared cameras to monitor temperature distribution during annealing and adjust furnace settings accordingly.

Conclusion

Silicon steel processing involves several stages where various challenges can arise affecting product quality and performance. By understanding these challenges and implementing solutions such as advanced temperature control systems, high-quality lubricants stress relief annealing (SRA), grinding/polishing for surface defects & more; manufacturers could improve their production efficiency while maintaining consistent product quality standards across different batches - ultimately leading towards better customer satisfaction levels too

Key Components of a Precision Slitting Line Explained

October 15, 2024 7:49 - no comments yetprecision slitting line are vital in various manufacturing sectors, where they convert wide coils of material into narrower strips with high accuracy. The efficiency and effectiveness of these operations hinge on several key components that work in concert to ensure optimal performance. Understanding these components is crucial for manufacturers looking to enhance productivity and maintain product quality. This article breaks down the essential elements of a precision slitting line, highlighting their functions and significance.

Unwind Station

The unwind station is the first component of a precision slitting line where the wide coil of material is loaded and prepared for processing. This station serves as the entry point for the material and is equipped with a spindle or mandrel that securely holds the coil in place. The unwind station often includes a tension control system that ensures the material is fed smoothly into the slitting line without any slippage or excessive force. Proper tension management is crucial, as it affects the quality of the slit and the overall integrity of the material.

Slitting Blades

Central to the slitting process, the blades are responsible for cutting the coil into narrower strips. Precision slitting lines typically utilize various blade types, including rotary, shear, and circular blades, each designed for specific materials and thicknesses. The sharpness and alignment of these blades are critical for achieving clean cuts and minimizing burr formation. Regular maintenance and timely replacement of blades are essential practices to ensure the reliability and efficiency of the slitting process.

Slitting Head

The slitting head is the component where the actual cutting occurs. It houses the blades and provides the necessary adjustments for positioning and alignment. This part of the slitting line is often equipped with features like automatic blade height adjustment and angle settings to accommodate different material thicknesses and types. High-precision slitting heads can significantly enhance the accuracy of the cuts and reduce the likelihood of defects in the final product.

Tension Control System

The tension control system plays a pivotal role in maintaining the proper tension of the material as it moves through the slitting line. This system typically consists of sensors and actuators that monitor and adjust the tension in real time. Proper tension is essential for preventing issues such as wrinkling, slippage, and uneven cuts. A well-designed tension control system enhances the overall efficiency of the slitting process and contributes to the consistent quality of the final strips.

Rewind Station

After the material has been cut, the rewind station takes over to collect the narrower strips. This component is similar to the unwind station but is focused on winding the slitted coils back onto spools or mandrels. The rewind station may include features such as automatic tension adjustments to ensure that the newly formed coils are wound uniformly and securely. Proper winding is crucial for preventing damage to the strips and ensuring ease of handling during subsequent processing or transportation.

Control System

A sophisticated control system is integral to the operation of a precision slitting line. This system typically includes a computer interface that allows operators to set parameters such as cutting speed, blade alignment, and tension levels. Advanced control systems may also offer real-time monitoring and diagnostics, enabling operators to identify potential issues before they escalate. Automation in the control system enhances efficiency, reduces the risk of human error, and improves overall production quality.

Edge Trim Removal System

During the slitting process, some material may be wasted as edge trims. An edge trim removal system is designed to efficiently collect and dispose of these trimmings. This not only helps in maintaining a clean work environment but also contributes to material conservation efforts. Some manufacturers recycle edge trims, turning waste into usable materials, thus promoting sustainability within their operations.

Dust and Debris Management

Effective dust and debris management systems are essential in precision slitting lines. During cutting, particles and debris can accumulate, potentially affecting the machinery’s operation and the quality of the slitted strips. Dust extraction units and filtration systems help maintain cleanliness and prevent contamination, ensuring that the slitting process runs smoothly and efficiently.

Safety Features

Safety is paramount in any manufacturing environment, and precision slitting lines are no exception. Key safety features may include emergency stop buttons, protective guards, and safety interlocks that prevent accidental operation. These features help protect operators from potential hazards associated with the machinery, ensuring a safe working environment.

Conclusion

In summary, the key components of a precision slitting line work together to ensure that the slitting process is efficient, accurate, and safe. Understanding the roles and functions of each component—from the unwind station to the safety features—enables manufacturers to optimize their operations and improve product quality. As industries continue to evolve and demand higher standards, investing in advanced slitting line technology will be essential for maintaining competitiveness and efficiency in the market. By prioritizing the functionality and maintenance of these critical components, manufacturers can enhance their production capabilities and deliver superior products to their customers

A Guide to Selecting the Right Transformer Core Cutting Machine for Your Needs

October 14, 2024 8:30 - no comments yetTransformer core slitting machine are specialized equipment used to cut magnetic cores for transformers. These machines play a crucial role in the production of transformers, as they enable the precise cutting of cores into specific shapes and sizes. With the increasing demand for transformers in various industries, the need for efficient and accurate core cutting machines has also grown. In this article, we will provide a comprehensive guide to selecting the right transformer core cutting machine for your needs.

Understanding Your Requirements

Before selecting a transformer core cutting machine, it is essential to understand your specific requirements. Consider the type of transformer you are producing, the size and shape of the core, and the material used. Different machines are designed for specific applications, so it is crucial to choose a machine that meets your needs. Additionally, consider the production volume, as high-volume production requires a machine with high-speed cutting capabilities.

Types of Transformer Core Cutting Machines

There are several types of transformer core cutting machines available, each with its unique features and capabilities. The most common types include mechanical cutting machines, laser cutting machines, and water jet cutting machines. Mechanical cutting machines use a cutting tool to cut the core, while laser cutting machines use a high-powered laser beam. Water jet cutting machines use a high-pressure jet of water to cut the core. Each type of machine has its advantages and disadvantages, and the choice depends on the specific requirements of your application.

Mechanical Cutting Machines

Mechanical cutting machines are the most traditional type of transformer core cutting machine. They are cost-effective and suitable for low-to-medium volume production. These machines use a cutting tool to cut the core and are available in various sizes and configurations. However, they can be time-consuming and may not be suitable for complex core designs. Mechanical cutting machines are ideal for small-scale production and prototyping.

Laser Cutting Machines

Laser cutting machines are highly accurate and efficient, making them suitable for high-volume production. They use a high-powered laser beam to cut the core, enabling precise cuts and complex designs. Laser cutting machines are ideal for cutting thin materials and are commonly used in the production of high-frequency transformers. However, they can be expensive and require specialized maintenance.

Water Jet Cutting Machines

Water jet cutting machines use a high-pressure jet of water to cut the core, making them suitable for cutting a wide range of materials. They are highly accurate and enable precise cuts, making them ideal for complex core designs. Water jet cutting machines are also cost-effective and require minimal maintenance. However, they can be noisy and generate a significant amount of water waste.

Key Features to Consider

When selecting a transformer core cutting machine, there are several key features to consider. These include the machine's accuracy, speed, and material handling capabilities. Additionally, consider the machine's maintenance requirements, noise level, and safety features. It is also essential to evaluate the machine's compatibility with your existing production line and the level of technical support provided by the manufacturer.

Evaluating Machine Performance

To ensure the machine meets your requirements, it is essential to evaluate its performance. Consider conducting a trial run or testing the machine with a sample core. This will enable you to assess the machine's accuracy, speed, and overall performance. Additionally, evaluate the machine's reliability and durability, as well as its ability to handle different materials and core sizes.

Conclusion

Selecting the right transformer core cutting machine for your needs requires careful consideration of your specific requirements, machine type, and key features. By understanding your needs and evaluating machine performance, you can ensure the efficient and accurate production of transformer cores. Remember to consider factors such as accuracy, speed, material handling, and maintenance requirements when making your selection. With the right machine, you can improve your production efficiency, reduce costs, and increase product quality

The Advantages of Dry Type Transformers in Harsh Environmental Conditions

October 13, 2024 3:24 - no comments yetDry type transformers have been gaining popularity in recent years due to their numerous benefits and advantages over traditional oil-filled transformers. One of the key areas where dry type transformers excel is in harsh environmental conditions, where their unique design and construction provide improved reliability and performance. In this article, we will explore the advantages of dry type transformers in harsh environmental conditions and why they are becoming the preferred choice for many industries and applications.

Advantages in High-Temperature Environments

dry type electrical transformer manufacturers are ideal for high-temperature environments, where traditional oil-filled transformers can struggle to maintain their performance. The dry type transformer's solid insulation system is designed to withstand high temperatures without degrading or losing its insulating properties. This means that dry type transformers can operate safely and efficiently in temperatures up to 180°C, making them perfect for applications such as deserts, tropical regions, or high-temperature industrial processes. Additionally, dry type transformers do not require cooling systems, which can be a significant advantage in high-temperature environments where cooling systems can be prone to failure.

Benefits in Humid and Corrosive Environments

Dry type transformers are also well-suited for humid and corrosive environments, where moisture and chemicals can damage traditional oil-filled transformers. The epoxy resin used in dry type transformers is resistant to moisture and chemicals, ensuring that the transformer remains operational even in the most challenging environments. This makes dry type transformers ideal for applications such as marine and offshore installations, where saltwater and humidity can be a significant concern. Additionally, dry type transformers are resistant to corrosion, which can be a major problem in environments where chemicals and moisture are present.

Advantages in High-Altitude Environments

Dry type transformers are also suitable for high-altitude environments, where the air pressure is lower, and the risk of electrical discharges is higher. The dry type transformer's solid insulation system is designed to withstand the lower air pressure and reduce the risk of electrical discharges, making it an ideal choice for applications such as mountainous regions or high-altitude industrial processes. Additionally, dry type transformers do not require derating at high altitudes, which means that they can maintain their full power output even in the most challenging environments.

Benefits in Seismic and Vibration-Prone Environments

Dry type transformers are also designed to withstand seismic and vibration-prone environments, where traditional oil-filled transformers can be prone to damage. The dry type transformer's compact and rugged design makes it ideal for applications such as earthquake-prone regions or industrial processes where vibrations are a concern. Additionally, dry type transformers are designed to meet the most stringent seismic standards, ensuring that they remain operational even in the most challenging environments.

Case Studies and Real-World Applications

There are many real-world applications where dry type transformers have proven their advantages in harsh environmental conditions. For example, dry type transformers have been used in offshore wind farms, where they have withstood the harsh marine environment and provided reliable power to the turbines. Additionally, dry type transformers have been used in high-temperature industrial processes, such as steel manufacturing, where they have maintained their performance and reliability even in the most challenging conditions.

Conclusion

In conclusion, dry type transformers offer numerous advantages in harsh environmental conditions, including high-temperature, humid and corrosive, high-altitude, and seismic and vibration-prone environments. Their unique design and construction provide improved reliability and performance, making them an ideal choice for many industries and applications. As the demand for reliable and efficient power systems continues to grow, the advantages of dry type transformers in harsh environmental conditions make them an attractive option for many users. Whether it's a high-temperature industrial process or a marine and offshore installation, dry type transformers are the perfect choice for any application where reliability and performance are critical