Whole melt extracts are a popular choice for vape disposables due to their high potency and flavorful profile. This type of extract is made using a process that involves freezing fresh cannabis buds and then extracting the trichomes to create a concentrated product that is rich in cannabinoids and terpenes.

Harvesting and Freezing Fresh Cannabis Buds

The first step in the extraction process is to harvest fresh cannabis buds at peak ripeness. Once the buds are collected, they are immediately frozen to preserve their trichomes and terpenes. Freezing the buds helps to prevent any degradation of the cannabinoids and ensures a high-quality product.

Extraction Methods for Whole Melt Extracts

After the buds have been frozen, they are then processed using a variety of methods such as cold water extraction, dry sift, or ice wax extraction. These methods involve sifting or washing the frozen buds to separate the trichomes from the plant material. The resulting product is a fine powder or resin that is rich in cannabinoids and terpenes.

Drying and Curing the Extract

Once the trichomes have been extracted, they are then dried and cured to remove any excess moisture and to enhance the flavor profile of the extract. This drying and curing process can take anywhere from a few days to a few weeks, depending on the desired consistency and flavor of the extract.

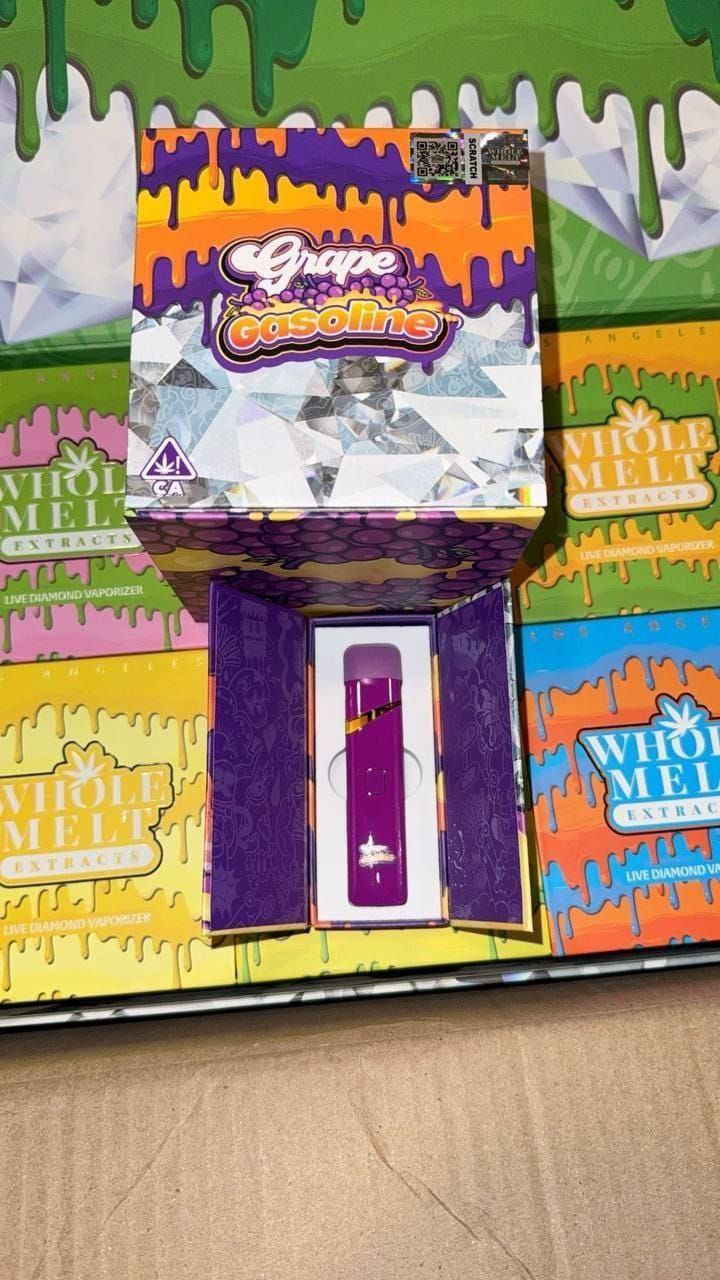

Packaging and Consumption

After the drying and curing process is complete, the whole melt extract is then packaged into vape disposables for easy consumption. These disposables are typically filled with a measured amount of whole melt extract, allowing for easy and convenient use on the go.

Benefits and Precautions of Whole Melt Extracts

Whole melt extracts are known for their high potency and flavorful profile, making them a popular choice for cannabis enthusiasts looking for a strong and enjoyable vaping experience. The extraction process used to create whole melt extracts ensures a high-quality product that is rich in cannabinoids and terpenes, providing users with a potent and flavorful vaping experience.

Tips for First-Time Users

For first-time users of whole melt disposables , it is important to start with a low dose and gradually increase as needed. This will allow you to gauge your tolerance and find the right dosage for your needs. Additionally, be sure to store your disposables in a cool, dark place to preserve the potency and flavor of the extract.

Conclusion

Overall, exploring the extraction process of whole melt extracts for disposables provides valuable insight into the production of these high-quality products . By understanding how whole melt extracts are made, you can better appreciate the craftsmanship and care that goes into creating these potent and flavorful vaping options. So, next time you reach for a whole melt disposable, you can vape with confidence knowing that you are enjoying a premium product that has been carefully crafted to deliver a top-notch vaping experience.

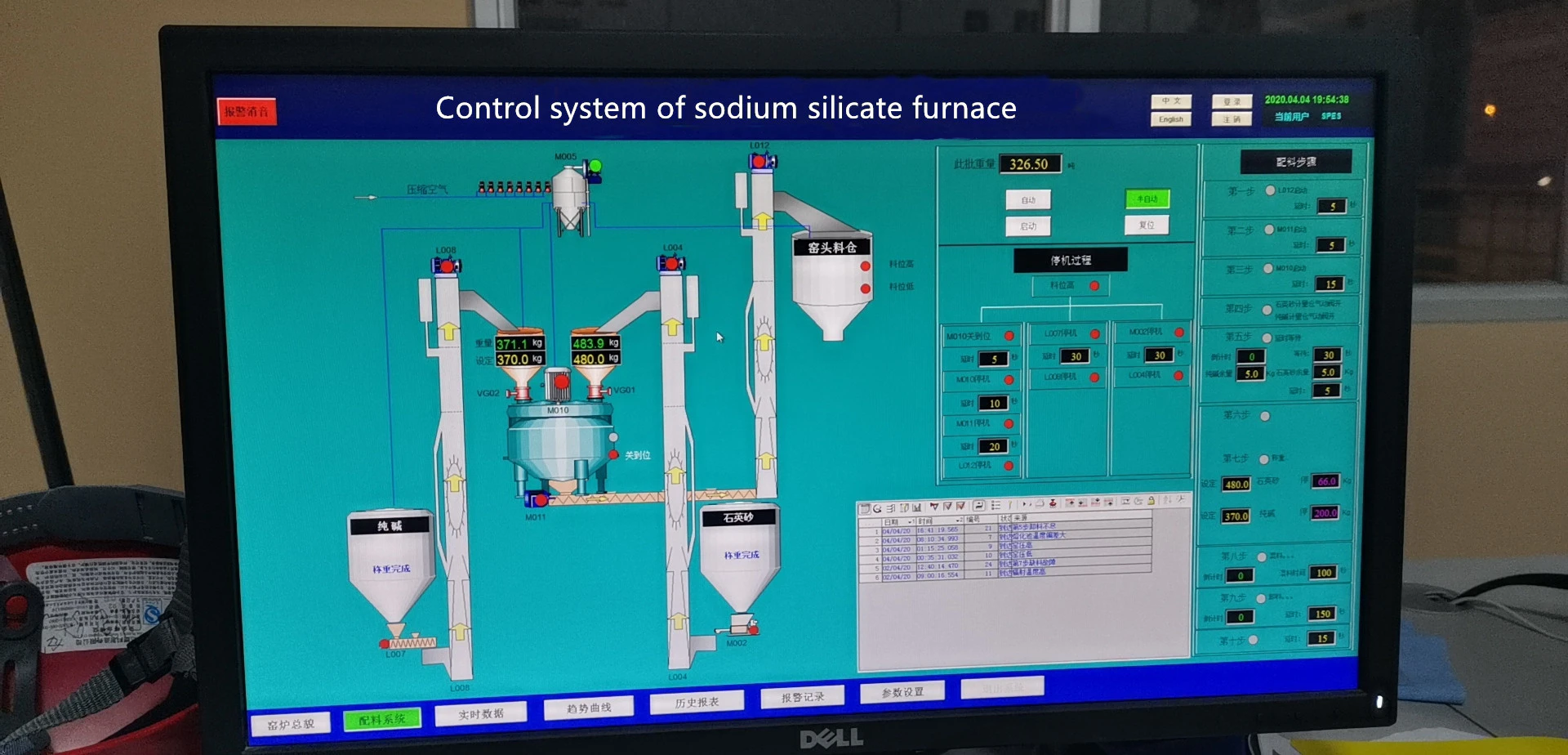

Safety Protocols for Operating a Sodium Silicate Plant

November 2, 2024 23:09 - no comments yetsodium silicate plant are facilities that produce sodium silicate, a compound used in various industries, including construction, detergents, and paper manufacturing. Operating such a plant requires strict adherence to safety protocols to protect workers, the environment, and the facility itself. This article outlines essential safety measures that should be implemented in sodium silicate plants.

Understanding Sodium Silicate Hazards

Sodium silicate can pose several hazards if not handled properly. It is caustic and can cause skin burns and eye damage. Inhalation of dust or fumes can lead to respiratory issues. Therefore, it is crucial for plant operators to understand these hazards and implement safety measures to mitigate risks. Regular training sessions should be conducted to educate employees about the potential dangers associated with sodium silicate.

Personal Protective Equipment (PPE)

The use of personal protective equipment is vital in ensuring the safety of workers in a sodium silicate plant. Employees should wear appropriate PPE, including gloves, goggles, face shields, and protective clothing. This equipment acts as a barrier against chemical exposure and should be regularly inspected and maintained. Employers must ensure that all workers are trained on the proper use of PPE and understand its importance in preventing injuries.

Proper Handling and Storage

Safe handling and storage of sodium silicate are critical to preventing accidents. Sodium silicate should be stored in a cool, dry place away from incompatible materials such as strong acids. Containers should be clearly labeled, and access to storage areas should be restricted to authorized personnel only. Additionally, proper lifting techniques should be employed when moving heavy containers to avoid injuries.

Emergency Response Procedures

In the event of an accident or spill, having a well-defined emergency response plan is essential. All employees should be familiar with the emergency procedures, including evacuation routes and the location of safety equipment such as eyewash stations and showers. Regular drills should be conducted to ensure that everyone knows how to respond effectively in an emergency. This preparedness can significantly reduce the impact of an incident.

Ventilation and Air Quality Control

Maintaining proper ventilation in a sodium silicate plant is crucial for ensuring air quality. Adequate ventilation systems should be installed to minimize the accumulation of harmful dust and fumes. Regular monitoring of air quality should be conducted to ensure that it remains within safe limits. If air quality standards are not met, immediate corrective actions should be taken to protect workers' health.

Training and Education

Continuous training and education are vital components of safety protocols in sodium silicate plants. Employees should receive training on the safe handling of chemicals, emergency response procedures, and the proper use of PPE. Refresher courses should be conducted regularly to keep safety practices at the forefront of employees' minds. A well-informed workforce is essential for maintaining a safe working environment.

Regular Safety Audits

Conducting regular safety audits is an effective way to identify potential hazards and ensure compliance with safety protocols. These audits should assess all aspects of plant operations, including equipment maintenance, employee practices, and emergency preparedness. Any deficiencies identified during audits should be addressed promptly to enhance overall safety.

Chemical Spill Management

In the event of a chemical spill, immediate action is required to minimize risks. Spill containment kits should be readily available, and employees should be trained on how to use them. The area should be evacuated, and appropriate authorities should be notified. Quick and efficient spill management can prevent further contamination and protect workers and the environment.

Environmental Considerations

Sodium silicate plants must also consider their environmental impact. Proper waste disposal methods should be implemented to prevent contamination of soil and water sources. Regular environmental assessments should be conducted to ensure compliance with regulations. By prioritizing environmental safety, plants can contribute to sustainable practices and protect local ecosystems.

Conclusion

In conclusion, operating a sodium silicate plant involves numerous safety considerations. By implementing strict safety protocols, providing adequate training, and maintaining a culture of safety, plant operators can protect their workers and the environment. Continuous improvement and adherence to safety measures are essential for the successful operation of sodium silicate plants.

Quality Control Measures in Liquid Detergent Production Processes

November 2, 2024 8:24 - no comments yetQuality control is essential in the production of liquid detergent making machine. It ensures that the final product meets the required standards for performance, safety, and consumer satisfaction. Quality control measures help in identifying defects and inconsistencies in the production process, allowing manufacturers to maintain high-quality products. This article explores various quality control measures implemented in liquid detergent production processes.

Raw Material Inspection

The quality of raw materials significantly impacts the final product. Before production begins, it is crucial to inspect all raw materials, including surfactants, solvents, and additives. Manufacturers should establish specifications for each raw material and conduct tests to verify their quality. This step helps in preventing substandard materials from entering the production line, ensuring that only high-quality ingredients are used in the formulation of liquid detergents.

In-Process Quality Control

In-process quality control involves monitoring the production process at various stages. This includes checking the mixing, heating, and cooling processes. Regular sampling and testing during production help in identifying any deviations from the standard operating procedures. By implementing in-process quality control measures, manufacturers can quickly address issues and make necessary adjustments to maintain product quality.

Final Product Testing

Once the liquid detergent is produced, it undergoes rigorous testing before packaging. This testing includes evaluating the product's viscosity, pH level, and cleaning efficiency. Manufacturers often conduct performance tests to ensure that the detergent effectively removes stains and dirt. Additionally, sensory evaluations, such as fragrance and color, are performed to meet consumer preferences. Final product testing is crucial in ensuring that the detergent meets quality standards and is safe for consumer use.

Stability Testing

Stability testing is essential to determine the shelf life of liquid detergents. This involves storing samples under various conditions, such as different temperatures and humidity levels, to observe any changes in the product over time. Manufacturers assess the physical and chemical properties of the detergent during stability testing. This information helps in formulating products that maintain their effectiveness and safety throughout their intended shelf life.

Packaging Quality Control

The packaging of liquid detergents plays a significant role in maintaining product quality. Quality control measures should be implemented to ensure that packaging materials are suitable for the product. This includes checking for leaks, ensuring proper sealing, and verifying that labels are accurate and informative. Proper packaging protects the detergent from contamination and degradation, ensuring that consumers receive a high-quality product.

Employee Training and Awareness

A well-trained workforce is vital for maintaining quality control in liquid detergent production. Manufacturers should invest in training programs that educate employees about quality standards and best practices. Employees should be aware of their roles in the production process and the importance of adhering to quality control measures. Regular training sessions help in reinforcing the significance of quality and encourage a culture of continuous improvement.

Regulatory Compliance

Compliance with industry regulations and standards is a critical aspect of quality control in liquid detergent production. Manufacturers must stay updated with local and international regulations regarding product safety and environmental impact. Regular audits and inspections help in ensuring compliance with these regulations. By adhering to legal requirements, manufacturers can avoid penalties and maintain a positive reputation in the market.

Consumer Feedback and Continuous Improvement

Gathering consumer feedback is an essential part of quality control. Manufacturers should actively seek input from consumers regarding their experiences with the product. This feedback can provide valuable insights into areas for improvement. By analyzing consumer feedback, manufacturers can make necessary adjustments to enhance product quality and meet evolving consumer preferences. Continuous improvement is key to maintaining a competitive edge in the liquid detergent market.

Conclusion

Quality control measures in liquid detergent production processes are crucial for ensuring product safety, effectiveness, and consumer satisfaction. From raw material inspection to final product testing, each step plays a vital role in maintaining high-quality standards. By implementing robust quality control measures, manufacturers can produce liquid detergents that meet consumer expectations and regulatory requirements. This commitment to quality not only enhances brand reputation but also fosters consumer trust and loyalty.

Innovations in Detergent Powder Manufacturing Technology

November 1, 2024 13:10 - no comments yetdetergent powder making machine are essential household products used for cleaning clothes and other fabrics. The manufacturing process of detergent powders has evolved significantly over the years. Innovations in technology have led to the development of more effective and environmentally friendly products. This article explores the latest advancements in detergent powder manufacturing technology.

Advancements in Raw Materials

The choice of raw materials is crucial in detergent powder manufacturing. Recent innovations include the use of biodegradable surfactants derived from natural sources. These materials not only enhance the cleaning efficiency but also reduce the environmental impact. Manufacturers are increasingly opting for plant-based ingredients, which are safer for both users and the environment.

Improved Formulation Techniques

Modern formulation techniques have revolutionized the way detergent powders are created. Innovations such as encapsulation technology allow for the controlled release of active ingredients during the washing process. This ensures that the detergent works effectively throughout the wash cycle, providing superior cleaning performance. Additionally, advancements in formulation have led to the development of concentrated powders that require less product per wash.

Energy-Efficient Manufacturing Processes

Energy consumption is a significant concern in the manufacturing industry. Recent innovations have focused on creating energy-efficient processes in detergent powder production. Techniques such as spray drying and fluidized bed granulation have been optimized to reduce energy usage. These methods not only lower production costs but also minimize the carbon footprint of manufacturing facilities.

Automation and Smart Manufacturing

The integration of automation and smart manufacturing technologies has transformed the detergent powder industry. Automated systems streamline production processes, reducing the likelihood of human error and increasing efficiency. Furthermore, the use of data analytics allows manufacturers to monitor production in real-time, enabling quick adjustments to maintain quality and consistency.

Sustainability Initiatives

Sustainability is a key focus in the detergent powder manufacturing sector. Innovations in packaging have led to the development of eco-friendly materials that reduce plastic waste. Many companies are now using recyclable or biodegradable packaging options. Additionally, manufacturers are exploring ways to minimize water usage during production, further contributing to sustainable practices.

Consumer-Centric Innovations

Understanding consumer preferences is essential for the success of detergent powders. Recent innovations have led to the creation of products that cater to specific consumer needs. For instance, hypoallergenic detergents are formulated for sensitive skin, while fragrance-free options are available for those who prefer minimal scents. These consumer-centric innovations enhance user satisfaction and loyalty.

Research and Development Investments

Investing in research and development is crucial for driving innovation in detergent powder manufacturing. Companies are allocating resources to explore new technologies and improve existing formulations. Collaborations with research institutions and universities are becoming more common, fostering innovation and ensuring that manufacturers stay ahead of market trends.

Global Market Trends

The global detergent powder market is witnessing significant growth, driven by rising consumer demand for effective cleaning products. Innovations in manufacturing technology are enabling companies to meet this demand while adhering to sustainability standards. As consumers become more environmentally conscious, manufacturers are focusing on creating products that align with these values.

Challenges in the Industry

Despite the advancements, the detergent powder manufacturing industry faces challenges. Regulatory compliance regarding environmental standards is becoming increasingly stringent. Manufacturers must navigate these regulations while continuing to innovate and meet consumer expectations. Additionally, competition in the market requires companies to differentiate their products through unique formulations and branding strategies.

Future Prospects

The future of detergent powder manufacturing technology looks promising. With ongoing advancements in materials, processes, and consumer insights, manufacturers are well-positioned to create innovative products. The focus on sustainability and efficiency will continue to drive research and development efforts, leading to even more effective and eco-friendly detergent powders in the coming years.

Conclusion

In conclusion, innovations in detergent powder manufacturing technology are transforming the industry. From improved raw materials to energy-efficient processes, these advancements are enhancing product performance while promoting sustainability. As manufacturers continue to invest in research and development, the future of detergent powders appears bright, with exciting possibilities on the horizon.

Understanding the Technology Behind 3 Inch Thermal Printers

October 31, 2024 12:37 - no comments yetThermal printing technology has revolutionized the way businesses handle printing tasks. This technology is widely used in various industries, including retail, logistics, and healthcare. Thermal printers operate by using heat to transfer ink onto paper, resulting in high-quality prints. Among the different types of thermal printers, 3-inch thermal printers are particularly popular due to their compact size and versatility. Understanding the technology behind these printers can help users appreciate their functionality and advantages.

How Thermal Printers Work

Thermal printers utilize a heat-sensitive printing process. They consist of a thermal print head that heats up and comes into contact with thermal paper. When the print head heats specific areas of the paper, it causes a chemical reaction that produces an image or text. There are two main types of thermal printing: direct thermal and thermal transfer. Direct thermal printing uses heat-sensitive paper, while thermal transfer printing uses a ribbon that transfers ink onto the paper. Both methods have their unique applications and benefits.

Components of a 3 Inch Thermal Printer

A 3 inch thermal printer comprises several essential components. The thermal print head is the most critical part, as it generates heat to create prints. The printer also includes a paper feed mechanism, which ensures that the paper is fed correctly through the printer. Additionally, a control board manages the printer's operations, including communication with connected devices. Some models may also feature a built-in cutter for automatic cutting of printed labels or receipts.

Advantages of 3 Inch Thermal Printers

3-inch thermal printers offer numerous advantages that make them an excellent choice for various applications. Their compact size allows for easy portability, making them ideal for mobile printing needs. These printers are also known for their speed, producing prints quickly without sacrificing quality. Furthermore, thermal printers require minimal maintenance since they have fewer moving parts compared to traditional inkjet or laser printers. This reliability makes them a preferred choice for businesses that require consistent performance.

Applications of 3 Inch Thermal Printers

The applications of 3-inch thermal printers are vast and varied. In retail, they are commonly used for printing receipts and labels. In logistics, these printers are essential for generating shipping labels and tracking information. Healthcare facilities utilize thermal printers for printing patient wristbands and medication labels. Additionally, these printers are increasingly used in mobile applications, such as ticketing and on-the-go printing solutions. Their versatility makes them suitable for a wide range of industries.

Choosing the Right Thermal Printer

When selecting a 3-inch thermal printer, several factors should be considered. First, assess the printer's print speed and resolution to ensure it meets your printing needs. Additionally, consider the connectivity options available, such as USB, Bluetooth, or Wi-Fi, to ensure compatibility with your devices. Battery life is another crucial factor for mobile printers, as longer battery life allows for extended use without interruptions. Finally, evaluate the printer's durability, especially if it will be used in demanding environments.

Maintenance of Thermal Printers

Proper maintenance is essential for ensuring the longevity and performance of thermal printers. Regularly cleaning the thermal print head helps maintain print quality and prevents issues such as smudging or fading. It is also important to use the correct type of thermal paper to avoid jams and other printing problems. Users should periodically check for software updates to ensure the printer operates efficiently and securely. Following these maintenance practices can significantly extend the lifespan of the printer.

Cost-Effectiveness of Thermal Printing

One of the significant advantages of thermal printing is its cost-effectiveness. Thermal printers generally have lower operating costs compared to traditional printers, as they do not require ink cartridges or toner. The cost of thermal paper is also relatively low, making it an economical choice for businesses that print frequently. Additionally, the durability and reliability of thermal printers reduce the need for repairs and replacements, further contributing to cost savings.

Future Trends in Thermal Printing Technology

As technology continues to evolve, so does thermal printing. Future trends in this field include advancements in print speed and quality, as well as the integration of smart technology. For instance, some manufacturers are developing printers that can connect to cloud services for easier management and storage of print jobs. Additionally, the demand for eco-friendly printing solutions is leading to the development of sustainable thermal paper options. These trends indicate a promising future for thermal printing technology.

Conclusion

In conclusion, understanding the technology behind 3-inch thermal printers reveals their importance in various industries. Their efficient printing process, compact size, and versatility make them a valuable asset for businesses. By considering factors such as print speed, connectivity, and maintenance, users can select the right thermal printer to meet their needs. As technology advances, the future of thermal printing looks bright, with new innovations on the horizon.

Inside the World of Thermal Printer Factories How They Work

October 30, 2024 17:16 - no comments yetthermal printer manufacturer are widely used in various industries for their efficiency and reliability. They utilize heat to transfer ink onto paper, making them ideal for printing labels, receipts, and tickets. Understanding how these printers work requires a closer look at the manufacturing processes involved in thermal printer factories.

The Basics of Thermal Printing Technology

Thermal printing technology operates on two main principles: direct thermal and thermal transfer. Direct thermal printers use heat paper that darkens when exposed to heat. In contrast, thermal transfer printers use a ribbon that melts onto the paper when heated. Both methods have their unique applications and advantages, making them popular choices in different sectors.

The Manufacturing Process of Printers

The manufacturing process of thermal printers involves several stages. It begins with the design phase, where engineers create blueprints for the printer's components. Once the design is finalized, the production of parts such as the print head, circuit boards, and casing begins. Each component is manufactured using precision machinery to ensure quality and consistency.

Quality Control in Thermal Printer Factories

Quality control is a critical aspect of thermal printer manufacturing. Factories implement strict quality assurance protocols to ensure that each printer meets industry standards. This includes testing components for durability, performance, and compatibility. Regular inspections are conducted throughout the production process to identify and rectify any issues early on.

The Role of Automation in Production

Automation plays a significant role in thermal printer factories. Many processes, such as assembly and testing, are automated to increase efficiency and reduce labor costs. Robotic arms and conveyor systems are commonly used to streamline production, allowing factories to produce large quantities of printers in a shorter time frame.

Sourcing Materials for Thermal Printers

The materials used in thermal printers are crucial for their performance and longevity. Factories source high-quality components, including heat-sensitive paper, ribbons, and electronic parts. Suppliers are carefully selected based on their ability to provide reliable materials that meet the factory's specifications.

Environmental Considerations in Manufacturing

Thermal printer factories are increasingly focusing on sustainability and reducing their environmental impact. This includes implementing eco-friendly practices such as recycling waste materials and using energy-efficient machinery. By adopting these measures, factories aim to minimize their carbon footprint while maintaining production efficiency.

The Importance of Research and Development

Research and development (R&D) play a vital role in the thermal printer industry. Factories invest in R&D to innovate and improve their products continually. This includes exploring new printing technologies, enhancing print quality, and developing more efficient manufacturing processes. Staying ahead of the competition requires a commitment to innovation.

Challenges Faced by Thermal Printer Manufacturers

Thermal printer manufacturers face various challenges in the industry. These include fluctuating material costs, competition from alternative printing technologies, and changing consumer demands. To remain competitive, factories must adapt to these challenges by optimizing their production processes and exploring new markets.

The Future of Thermal Printing Technology

The future of thermal printing technology looks promising. As industries continue to evolve, the demand for efficient and reliable printing solutions will grow. Manufacturers are exploring advancements in printing speed, quality, and versatility. The integration of smart technology and connectivity features is also becoming increasingly important in meeting customer needs.

Conclusion: The Impact of Thermal Printer Factories

Thermal printer factories play a crucial role in the global printing industry. By understanding how these factories operate, we can appreciate the complexity and precision involved in manufacturing thermal printers. As technology continues to advance, these factories will remain at the forefront of innovation, providing essential printing solutions for various applications