Whole melt extracts are a popular choice for vape disposables due to their high potency and flavorful profile. This type of extract is made using a process that involves freezing fresh cannabis buds and then extracting the trichomes to create a concentrated product that is rich in cannabinoids and terpenes.

Harvesting and Freezing Fresh Cannabis Buds

The first step in the extraction process is to harvest fresh cannabis buds at peak ripeness. Once the buds are collected, they are immediately frozen to preserve their trichomes and terpenes. Freezing the buds helps to prevent any degradation of the cannabinoids and ensures a high-quality product.

Extraction Methods for Whole Melt Extracts

After the buds have been frozen, they are then processed using a variety of methods such as cold water extraction, dry sift, or ice wax extraction. These methods involve sifting or washing the frozen buds to separate the trichomes from the plant material. The resulting product is a fine powder or resin that is rich in cannabinoids and terpenes.

Drying and Curing the Extract

Once the trichomes have been extracted, they are then dried and cured to remove any excess moisture and to enhance the flavor profile of the extract. This drying and curing process can take anywhere from a few days to a few weeks, depending on the desired consistency and flavor of the extract.

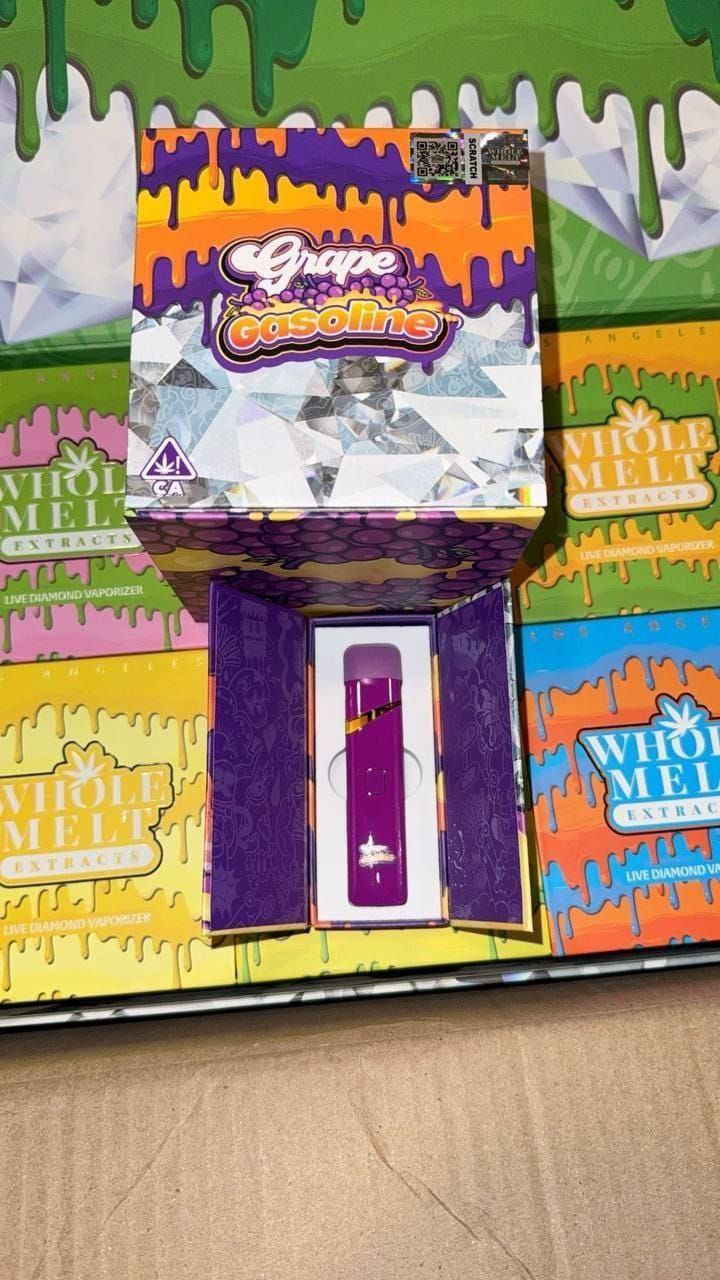

Packaging and Consumption

After the drying and curing process is complete, the whole melt extract is then packaged into vape disposables for easy consumption. These disposables are typically filled with a measured amount of whole melt extract, allowing for easy and convenient use on the go.

Benefits and Precautions of Whole Melt Extracts

Whole melt extracts are known for their high potency and flavorful profile, making them a popular choice for cannabis enthusiasts looking for a strong and enjoyable vaping experience. The extraction process used to create whole melt extracts ensures a high-quality product that is rich in cannabinoids and terpenes, providing users with a potent and flavorful vaping experience.

Tips for First-Time Users

For first-time users of whole melt disposables , it is important to start with a low dose and gradually increase as needed. This will allow you to gauge your tolerance and find the right dosage for your needs. Additionally, be sure to store your disposables in a cool, dark place to preserve the potency and flavor of the extract.

Conclusion

Overall, exploring the extraction process of whole melt extracts for disposables provides valuable insight into the production of these high-quality products . By understanding how whole melt extracts are made, you can better appreciate the craftsmanship and care that goes into creating these potent and flavorful vaping options. So, next time you reach for a whole melt disposable, you can vape with confidence knowing that you are enjoying a premium product that has been carefully crafted to deliver a top-notch vaping experience.

Analyzing Market Trends in Wholesale Wine Packaging Solutions

septiembre 28, 2024 7:45 - no comments yetWhen it comes to choosing the right packaging solutions for your wine business, it's essential to stay up-to-date on the latest market trends. As the wine industry continues to grow, so does the demand for innovative and high-quality packaging options for wine bottles. In this section, we will delve into some of the key market trends in wholesale wine packaging solutions to help you make informed decisions for your business.

The Rise of Sustainable and Eco-Friendly Materials

One of the major trends in cardboard wine boxes wholesale packaging solutions is the shift towards sustainable and eco-friendly materials. With increasing awareness of environmental issues, many consumers are looking for products that are not only high quality but also environmentally friendly. As a result, the demand for cardboard wine boxes made from recycled materials or sourced from sustainable forests is on the rise. Businesses that prioritize sustainability in their packaging are more likely to attract environmentally conscious customers and build a positive brand reputation.

Customization and Branding in Wine Packaging

Another trend in wholesale wine packaging solutions is the focus on customization and branding. In a crowded marketplace, it's essential for wine businesses to stand out and create a memorable experience for consumers. Customized cardboard wine boxes with unique designs, logos, and can help businesses differentiate their products and establish a strong brand presence. Whether it's a sleek and modern design for a premium wine bottle or a colorful and vibrant package for a playful and approachable wine, customization plays a key role in creating a cohesive brand identity.

The Impact of E-commerce on Wine Packaging

Additionally, the rise of e-commerce has significantly impacted the packaging industry, including wholesale wine packaging solutions. With more consumers shopping online for wine, packaging plays a crucial role in protecting bottles during shipping and creating a positive unboxing experience for customers. Durable cardboard wine boxes that are designed to withstand the rigors of shipping while still looking attractive and professional are in high demand. As online wine sales continue to grow, businesses need to invest in packaging solutions that not only protect their products but also enhance the overall customer experience.

Convenience and Practicality in Wine Packaging

Furthermore, convenience and practicality are also important considerations in wholesale wine packaging solutions. Consumers are looking for packaging that is easy to use, store, and recycle. Cardboard wine boxes with carry handles, easy-to-open seals, and stackable designs can make it easier for customers to transport and store their wine bottles. Additionally, packaging that is fully recyclable and biodegradable not only appeals to environmentally conscious consumers but also helps businesses meet sustainability goals and reduce their carbon footprint.

Staying Ahead of the Competition with Market Trends

In conclusion, staying abreast of market trends in wholesale wine packaging solutions is essential for businesses looking to thrive in the competitive wine industry. From sustainable materials and customization to e-commerce-friendly designs and convenience features, the right packaging can make a significant difference in attracting customers, protecting products, and building a strong brand identity. By understanding and embracing these trends, wine businesses can make informed decisions when selecting quality wholesale cardboard wine boxes that meet the needs and expectations of their customers.

Choosing the Right Wholesale Cardboard Wine Boxes for Your Business

In conclusion, when looking for quality wholesale cardboard wine boxes, it's essential to consider features such as durability, size, and design. These factors can ensure that your wine bottles are securely packaged and well-protected during transportation. By investing in high-quality boxes, you can enhance the overall presentation of your products and provide a better customer experience. Take the time to carefully evaluate these essential features to find the perfect cardboard wine boxes for your business needs. Cheers to packaging success!

How to Create a Memorable Unboxing Experience with Wine Gift Boxes

septiembre 28, 2024 7:45 - no comments yetWhen it comes to giving the gift of wine, presentation is key. A beautifully designed wine gift box can elevate the entire gift-giving experience and leave a lasting impression on the recipient. Creating a memorable unboxing experience with wine gift boxes is a great way to show someone you care and make them feel special.

Designing the Perfect Box

One of the first things to consider when creating a memorable unboxing experience with wine gift boxes is the design of the box itself. Choose a box that not only fits the wine bottle gift box wholesale securely but also reflects the personality of the recipient or the occasion. Whether you opt for a classic, elegant design or something more whimsical and fun, the box should make a statement and set the tone for what’s inside.

Choosing High-Quality Materials

Another important aspect to consider is the materials used in the construction of the wine gift box. High-quality materials not only add to the overall aesthetic appeal but also demonstrate the care and thought put into the gift. Opt for sturdy cardboard or wood boxes that feel substantial and luxurious in the hands of the recipient.

Adding a Personal Touch

Personalization is another key element in creating a memorable unboxing experience with wine gift boxes. Adding a personalized touch, such as a handwritten note or a custom label, can make the gift feel even more special and unique. Consider adding the recipient’s name or a special message to the box to make it truly one-of-a-kind.

Enhancing the Unboxing Experience

Incorporating additional elements into the wine gift box can also enhance the unboxing experience. Consider adding a small gift, such as chocolates or wine accessories, to complement the bottle of wine and make the gift feel more complete. You could also include a printed booklet or card with information about the wine, pairing suggestions, or a personal note from the sender.

The Art of Presentation

The presentation of the wine gift box is just as important as the contents inside. Make sure the box is wrapped beautifully with high-quality ribbon or a decorative bow to build anticipation and create a sense of excitement for the recipient. Adding a finishing touch, such as a wax seal or a decorative sticker, can further elevate the unboxing experience.

Setting the Stage

Finally, consider the timing and setting of the gift presentation. Whether you’re giving the wine gift box at a special occasion or simply as a gesture of appreciation, take the time to present it thoughtfully and with care. Consider setting the stage with candles, flowers, or other decorative elements to create a memorable and intimate moment for the recipient.

Conclusion

In conclusion, creating a memorable unboxing experience with wine gift boxes is all about attention to detail and thoughtful consideration. By choosing a beautifully designed box, using high-quality materials, personalizing the gift, incorporating additional elements, and presenting it with care, you can make the gift of wine truly unforgettable. So next time you’re giving the gift of wine, remember that the experience starts even before the bottle is opened.

Understanding the Certification Process for Circular Connectors

septiembre 24, 2024 0:16 - no comments yetcircular push pull connector ors are an essential component in various industries, providing a reliable way to transmit power, signals, and data between different electronic devices. However, ensuring the quality and reliability of these connectors is crucial to prevent potential issues or failures in the overall system. This is where the certification process for circular connectors comes into play.

The Importance of Certification

Certification is a way to verify that a product meets certain industry standards and specifications, ensuring that it is safe, reliable, and performs as intended. When it comes to circular connectors, there are several key aspects that manufacturers need to consider in order to successfully navigate the certification process.

Compliance with Industry Standards

One of the most important aspects of certification for circular connectors is compliance with industry standards. These standards are developed by organizations such as the International Electrotechnical Commission (IEC) or the Society of Automotive Engineers (SAE), and outline the requirements for performance, safety, and reliability of circular connectors. In order to obtain certification, manufacturers need to demonstrate that their connectors meet these standards through rigorous testing and evaluation.

Testing for Performance Parameters

In addition to compliance with industry standards, certification for circular connectors also involves testing for specific performance parameters. This can include testing for factors such as signal integrity, voltage and current ratings, environmental durability, and resistance to various factors such as vibration, temperature, or moisture. By testing these parameters, manufacturers can ensure that their connectors will perform reliably in real-world conditions.

Ensuring Compatibility

Another important aspect of the certification process for circular connectors is ensuring compatibility with other devices or systems. This involves testing the connector’s compatibility with different types of cables, interfaces, or devices to ensure seamless integration and communication. Compatibility testing is essential to prevent issues such as signal interference, data loss, or damage to connected devices.

Regulatory Compliance

In addition to technical requirements, certification for circular connectors also involves compliance with various regulatory requirements. Depending on the industry or application, manufacturers may need to obtain certification from regulatory bodies such as the Federal Communications Commission (FCC) or the European Union’s CE marking. These certifications ensure that the connectors meet specific safety and performance standards required for use in a particular market.

Certification Marks and Customer Assurance

Once a manufacturer has successfully completed the certification process for their circular connectors, they can affix the appropriate certification marks on their products. This provides customers with the assurance that the connectors have been tested and approved by recognized authorities, giving them confidence in the reliability and quality of the product.

Conclusion

In conclusion, the certification process for circular connectors is a critical step in ensuring the quality, reliability, and safety of these essential components. By complying with industry standards, testing for performance parameters, ensuring compatibility, and meeting regulatory requirements, manufacturers can demonstrate that their connectors meet the highest standards of quality and performance. This not only benefits the manufacturers themselves but also provides customers with the assurance that they are purchasing a reliable and trustworthy product for their electronic systems.

Exploring the Applications of Push Pull Connectors Across Industries

septiembre 24, 2024 0:12 - no comments yetPush pull connectors are versatile and reliable components that find applications across various industries. One of the key industries where push pull connectors are extensively used is the medical industry. In medical devices such as patient monitoring equipment, endoscopes, and imaging systems, push pull connectors provide a secure and reliable connection that ensures uninterrupted data transmission and power supply. Moreover, the compact design of push pull connectors is particularly beneficial in medical applications where space is limited, such as in wearable medical devices or surgical equipment.

Industrial Sector Applications

In the industrial sector, push pull connectors are commonly used in automation systems, robotics, and machinery. These connectors are designed to withstand harsh environmental conditions, including high temperatures, vibrations, and moisture, making them ideal for industrial applications where reliability and durability are critical. The quick and easy mating and unmating of push pull connectors also help in reducing downtime during maintenance or repair operations, thus improving overall efficiency in industrial processes.

Automotive Industry Applications

The automotive industry also benefits greatly from the use of push pull connectors, where they are used in various applications such as sensors, lighting systems, and infotainment systems. The compact and lightweight design of push pull connectors makes them ideal for use in the confined spaces of modern vehicles. Additionally, the secure locking mechanism of push pull connectors ensures a stable and reliable connection, even in high-vibration environments.

Telecommunications Sector Applications

In the telecommunications sector, push pull connectors are widely used in networking equipment, fiber optic systems, and data centers. The high data transmission rates and low signal loss offered by push pull connectors make them a popular choice for applications that require high-performance connectivity. Moreover, the ease of installation and maintenance of push pull connectors makes them an efficient solution for telecommunications infrastructure that needs to be constantly upgraded or expanded.

Aerospace and Defense Industry Applications

In the aerospace and defense industry, push pull connectors play a crucial role in ensuring the reliability and safety of electronic systems in aircraft, satellites, and military vehicles. These connectors are designed to meet stringent requirements for high-performance, ruggedness, and resistance to extreme temperatures and vibrations. The self-locking feature of push pull connectors is particularly important in aerospace and defense applications, where the integrity of the electrical connection is critical for mission success.

Entertainment and Broadcast Industry Applications

Push pull connectors are also commonly used in the entertainment and broadcast industry, where they are used in audio and video equipment, lighting systems, and stage productions. The simplicity and reliability of push pull connectors make them an ideal choice for applications that require frequent set-up and tear-down of equipment. Additionally, the high-quality signal transmission provided by push pull connectors ensures a seamless and uninterrupted performance during live events and broadcasts.

Versatility and Reliability Across Industries

Overall, the wide range of applications of push pull connectors across industries highlights their versatility, reliability, and efficiency in providing secure and high-performance connectivity solutions for various electronic systems and equipment.

Conclusion

In conclusion, push-pull connectors are a convenient and versatile option for various applications due to their easy installation and secure fastening. With features such as self-locking mechanisms and high reliability, these connectors offer a reliable and efficient solution for connecting devices in a variety of industries. Whether you are in the medical, automotive, or aerospace sector, push-pull connectors can provide a simple and effective way to ensure smooth and reliable connections. Consider incorporating push-pull connectors into your next project to take advantage of their many benefits and simplify your connectivity needs.

The Significance of Customization in Electrical Connector Solutions

septiembre 24, 2024 0:12 - no comments yetWhen it comes to selecting circular push-pull connectors for your electrical systems, customization plays a crucial role in ensuring optimal performance and compatibility. Every application is unique, with specific requirements and challenges that must be addressed in order to achieve the desired results.

The Benefits of Tailored Design

One of the key advantages of customization in electrical connector solutions is the ability to tailor the design to meet the specific needs of your application. This includes factors such as size, shape, material, and electrical specifications. By working closely with a manufacturer that offers customized solutions, you can ensure that the connectors you select are perfectly suited to your requirements, providing a seamless and efficient connection for your electrical systems.

Incorporating Additional Features and Functionalities

Customization also allows for the incorporation of additional features and functionalities that may be necessary for your application. This could include features such as keying options for mating connectors, environmental sealing for protection against moisture and dust, or EMI/RFI shielding for improved signal integrity. By customizing your connectors, you can ensure that they will perform reliably in even the most demanding operating conditions.

Optimizing for Application Environment

Another important aspect of customization is the ability to optimize the connectors for the specific application environment. Factors such as temperature extremes, vibration, shock, and exposure to chemicals or other harsh substances can all impact the performance and longevity of electrical connectors. By customizing the design and materials used in the connectors, you can ensure that they will withstand the rigors of your application environment and provide reliable performance over the long term.

Streamlining Installation and Maintenance

In addition to improving performance and reliability, customization can also help to streamline the installation and maintenance of your electrical systems. By designing connectors that are tailored to your specific requirements, you can simplify the installation process and reduce the risk of errors or compatibility issues. This can help to minimize downtime and ensure that your systems are up and running as quickly as possible.

Ensuring Compliance with Industry Standards

Customization can also play a key role in ensuring compliance with industry standards and regulations. By working with a manufacturer that has experience with the relevant standards and certifications, you can ensure that your connectors meet all necessary requirements for safety, performance, and reliability. This can help to avoid costly delays or rework that can arise from using off-the-shelf connectors that may not meet industry standards.

Conclusion

In conclusion, customization is a critical factor to consider when selecting circular push-pull connectors for your electrical systems. By tailoring the design, materials, and features of the connectors to meet your specific requirements, you can ensure optimal performance, reliability, and compatibility for your applications. Whether you need connectors that can withstand extreme environments, provide enhanced functionality, or meet industry standards, customization can help you achieve the best possible results for your electrical systems.