Diesel Generators for Corrosive Atmospheres Ensuring Reliable Power Supply in Challenging Environments

мая 6, 2025 0:01 - no comments yetIntroduction

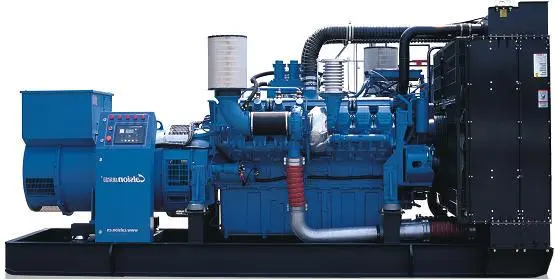

In industrial settings where corrosive atmospheres are present, ensuring a reliable power supply is essential for maintaining operations and productivity. Diesel generators are a popular choice for providing backup power in such environments due to their robust design, durability, and ability to withstand harsh conditions. In this article, we will explore the considerations, challenges, and solutions related to using diesel generators in corrosive atmospheres, highlighting the importance of selecting the right equipment and maintenance practices to ensure uninterrupted power supply.

Understanding Corrosive Atmospheres

Corrosive atmospheres are environments where various chemical substances, such as acids, salts, and moisture, are present in the air. These substances can react with the materials of equipment and infrastructure, leading to corrosion and degradation over time. 300kw diesel generator for remote relief projects like chemical plants, refineries, wastewater treatment plants, and marine environments are commonly exposed to corrosive atmospheres due to the nature of their operations.

The Impact of Corrosion on Diesel Generators

Diesel generators are complex systems comprised of various components, including engines, alternators, fuel systems, cooling systems, and electrical controls. Each of these components is susceptible to corrosion when exposed to corrosive atmospheres. The consequences of corrosion on diesel generators can be severe, ranging from reduced efficiency and performance to complete system failure.

One of the primary concerns with corrosion in diesel generators is the impact on critical components such as the engine block, fuel tanks, and electrical connections. Corrosion can compromise the structural integrity of these components, leading to leaks, short circuits, and mechanical failures. In addition, corrosion can hinder the proper functioning of moving parts, such as pistons and valves, causing operational issues and increasing maintenance requirements.

Challenges of Operating Diesel Generators in Corrosive Atmospheres

Operating diesel generators in corrosive atmospheres presents several challenges that need to be addressed to ensure the reliability and longevity of the equipment. Some of the key challenges include:

1. Material Selection: Choosing the right materials for constructing diesel generator components is crucial in resisting corrosion. Common materials used in diesel generators, such as steel, aluminum, and copper, may not be suitable for prolonged exposure to corrosive atmospheres. Specialized coatings, alloys, and corrosion-resistant materials need to be considered to enhance the durability of the equipment.

2. Maintenance Requirements: Regular maintenance is essential for preventing and mitigating corrosion in diesel generators. In corrosive atmospheres, maintenance tasks such as cleaning, lubrication, and inspection need to be performed more frequently to detect and address corrosion issues promptly. Failure to maintain the equipment properly can accelerate the corrosion process and lead to premature failure.

3. Ventilation and Air Quality: Corrosive atmospheres often contain airborne contaminants that can enter the diesel generator through ventilation systems and air intakes. These contaminants can accelerate corrosion and cause damage to internal components. Proper ventilation design and filtration systems are necessary to minimize the ingress of corrosive agents and maintain the air quality within the generator enclosure.

4. Environmental Factors: Environmental conditions, such as temperature, humidity, and exposure to saltwater or chemicals, can exacerbate corrosion in diesel generators. Extreme temperatures can promote condensation and corrosion, while high humidity levels can increase the risk of moisture-related damage. Protective measures, such as insulation, dehumidification, and corrosion inhibitors, are essential to safeguard the equipment from environmental threats.

Solutions for Mitigating Corrosion in Diesel Generators

To address the challenges of operating diesel generators in corrosive atmospheres, several solutions and best practices can be implemented to enhance the performance and longevity of the equipment. Some of the effective strategies for mitigating corrosion in diesel generators include:

1. Corrosion-Resistant Coatings: Applying specialized coatings and finishes to critical components of diesel generators can provide an additional layer of protection against corrosion. Epoxy coatings, polyurethane paints, and galvanizing treatments are commonly used to prevent the penetration of corrosive agents and extend the service life of the equipment.

2. Stainless Steel Components: Utilizing stainless steel components in key areas of the diesel generator, such as exhaust systems, fuel tanks, and pipework, can significantly reduce the risk of corrosion. Stainless steel is known for its high resistance to corrosion, making it an ideal choice for withstanding the harsh conditions of corrosive atmospheres.

3. Regular Inspections and Maintenance: Implementing a proactive maintenance schedule that includes regular inspections, cleaning, and lubrication can help identify and address corrosion issues before they escalate. Visual inspections, corrosion monitoring, and testing of protective coatings should be performed routinely to ensure the integrity of the equipment.

4. Proper Ventilation Design: Designing the ventilation system of the diesel generator enclosure to minimize the ingress of corrosive contaminants is essential for preventing corrosion-related damage. Installing air filters, intake screens, and moisture traps can help maintain a clean and dry environment within the generator enclosure, reducing the risk of corrosion.

5. Corrosion Inhibitors: Using corrosion inhibitors and rust preventatives in fuel systems, cooling systems, and electrical connections can protect vulnerable components from corrosion. These chemical treatments form a protective barrier on metal surfaces, preventing the formation of rust and corrosion in corrosive environments.

6. Environmental Monitoring: Monitoring environmental conditions, such as temperature, humidity, and chemical exposure, can help identify potential corrosion risks and take preventive measures accordingly. Installing sensors, alarms, and control systems to monitor and regulate the operating environment of the diesel generator can improve the equipment's resilience to corrosive atmospheres.

Case Studies and Success Stories

Several industries have successfully implemented diesel generators in corrosive atmospheres by adopting the best practices and solutions discussed above. Case studies and success stories from different sectors, such as marine, oil and gas, and industrial manufacturing, demonstrate the effectiveness of corrosion mitigation strategies in ensuring the reliable operation of diesel generators.

1. Marine Applications: In marine environments where saltwater corrosion is a significant concern, marine-grade diesel generators with stainless steel components and protective coatings have been deployed to provide backup power on ships and offshore platforms. Regular maintenance and environmental monitoring help prevent corrosion and ensure the continuous operation of the generators in challenging maritime conditions.

2. Oil and Gas Industry: Oil refineries and petrochemical plants often face corrosive atmospheres due to the presence of acidic gases and chemicals in the air. Diesel generators equipped with corrosion-resistant materials, such as duplex stainless steel and composite coatings, have been installed to withstand the harsh environment and maintain power supply during emergencies. Stringent maintenance protocols and corrosion control measures are implemented to safeguard the generators from corrosion damage.

3. Industrial Manufacturing: Corrosive atmospheres in industrial manufacturing facilities, such as chemical processing plants and wastewater treatment facilities, pose a threat to the reliability of diesel generators. By implementing corrosion-resistant coatings, stainless steel components, and advanced monitoring systems, these facilities have optimized the performance and longevity of their generators in corrosive environments. Regular inspections and maintenance practices are essential for ensuring the uninterrupted operation of the equipment.

Conclusion

Diesel generators play a critical role in providing backup power in corrosive atmospheres, where maintaining a reliable power supply is essential for sustaining operations and ensuring safety. By understanding the impact of corrosion on diesel generators, addressing the challenges of operating in corrosive atmospheres, and implementing effective solutions for mitigating corrosion, industrial facilities can optimize the performance and longevity of their backup power systems.

Choosing the right materials, conducting regular maintenance, designing proper ventilation systems, and utilizing corrosion inhibitors are key strategies for protecting diesel generators from corrosion damage. Case studies and success stories across various industries highlight the importance of adopting best practices and corrosion mitigation techniques to ensure the continuous operation of diesel generators in challenging environments.

In conclusion, diesel generators for corrosive atmospheres require careful consideration, proactive maintenance, and strategic planning to overcome the challenges posed by corrosion. By implementing the recommendations outlined in this article, industrial facilities can enhance the resilience and reliability of their backup power systems, ensuring uninterrupted power supply in the face of corrosive threats.