Custom Automotive The Injection Molding Solutions for High Performance

June 14, 2025 0:46 - no comments yetIn the highly competitive automotive industry, achieving high performance often hinges on the quality and precision of component manufacturing. Custom automotive injection molding solutions are crucial for delivering parts that meet strict safety standards, enhance vehicle durability, and offer superior functional performance. These tailored solutions enable manufacturers to produce complex shapes with tight tolerances, ensuring each part fits precisely and performs reliably throughout the lifespan of the vehicle. By focusing on customization, automotive brands can innovate and offer advanced features that set their vehicles apart in terms of both aesthetics and functionality.

The Significance of Customization in Automotive Components

Custom automotive injection molding goes beyond standard manufacturing techniques, offering tailored solutions that cater specifically to the unique specifications of each vehicle model. In the automotive sector, every component must endure extreme conditions, including high temperatures, mechanical stress, and exposure to various chemicals. Standard parts often fall short in providing the desired performance, prompting manufacturers to adopt custom solutions designed to optimize strength, flexibility, and environmental resistance. Custom molds are crafted to produce parts with intricate geometries, seamless finishes, and enhanced durability, which are essential for the demanding performance expectations of modern vehicles.

Designing for Superior Performance and Precision

Creating high-performance automotive parts through custom injection molding starts with meticulous design and engineering. Engineers utilize advanced CAD (Computer-Aided Design) software to develop detailed models that optimize material flow, minimize potential defects, and incorporate complex features. Design considerations also include the placement of ribs, bosses, and other reinforcing features to improve structural integrity without adding unnecessary weight. Cooling channels within molds are strategically placed to ensure uniform temperature distribution, which prevents warping and promotes dimensional stability. This sophisticated design process is vital for delivering parts that not only meet precise specifications but also enhance overall vehicle performance.

Cutting-Edge Materials and Manufacturing Techniques

The key to high-performance injection molding lies in selecting the right materials and employing advanced manufacturing processes. Automotive parts subjected to mechanical stress or extreme environmental conditions require materials like reinforced nylons, polycarbonates, or thermoplastic elastomers that provide the necessary strength and heat resistance. Modern manufacturing techniques, including high-precision CNC machining and EDM (Electrical Discharge Machining), facilitate the creation of complex molds with unparalleled accuracy. Surface treatments, such as texturing or coating, are also applied to improve wear resistance and ensure long-lasting performance. These combined efforts result in molds capable of producing components that meet the exacting demands of high-performance vehicles.

Maintaining Quality and Reliability in Production

Consistency is paramount when producing high-performance automotive parts, and quality assurance measures are integral to achieving this goal. Leading manufacturers implement rigorous testing at every stage, from mold fabrication to the final production run. Precision measurement tools and non-destructive testing methods such as 3D scanning and dye penetrant inspections ensure that each mold and resulting part adheres strictly to dimensional and quality standards. Prototype testing and pilot runs help identify and rectify potential issues before full-scale manufacturing. This meticulous quality control process guarantees that every component performs reliably under real-world conditions, reinforcing safety and customer satisfaction.

Innovations Shaping the Future of Injection Molding

As automotive technology evolves, so do the solutions provided by injection molding specialists. The industry is increasingly embracing innovations such as multi-material molding, which allows for the integration of different materials within a single part, improving performance and reducing assembly time. Additive manufacturing techniques are also gaining ground for rapid prototyping and producing complex internal features that traditional methods struggle with. Additionally, smarter mold designs incorporating sensors and automation are helping manufacturers monitor and optimize the molding process in real time. These innovations drive improvements in production efficiency, part quality, and overall vehicle performance, ensuring automakers stay ahead in an increasingly competitive marketplace.

Partnering for Success in High-Performance Automotive Parts

Choosing the right partner for custom automotive injection molding solutions is a strategic decision that can significantly impact a manufacturer’s success. Leading mold makers bring extensive expertise, state-of-the-art technology, and deep knowledge of the automotive industry’s specific needs. Collaborating with experienced manufacturers allows for tailored solutions that address unique design challenges, material selections, and performance requirements. A reliable partner will prioritize quality, innovation, and on-time delivery, providing continuous support throughout the development and production process. In a field where every component contributes to vehicle safety and performance, partnering with a specialized injection molding solution provider ensures that automotive companies can meet their high standards and deliver vehicles that stand out for their reliability and excellence.

In conclusion, custom automotive injection molding solutions are indispensable for achieving high-performance standards in today’s competitive automotive landscape. From innovative design and material selection to rigorous quality control and embracing new manufacturing technologies, these tailored solutions enable automakers to produce parts that excel in durability, functionality, and safety. As automotive engineering continues to push the boundaries of performance and complexity, the importance of customized injection molding solutions will only grow, playing a pivotal role in shaping the future of high-performance vehicles.

Custom Automotive These Injection Molding Solutions for High Performance

June 14, 2025 0:46 - no comments yetIn the highly competitive automotive industry, achieving high performance often hinges on the quality and precision of component manufacturing. Custom automotive injection molding solutions are crucial for delivering parts that meet strict safety standards, enhance vehicle durability, and offer superior functional performance. These tailored solutions enable manufacturers to produce complex shapes with tight tolerances, ensuring each part fits precisely and performs reliably throughout the lifespan of the vehicle. By focusing on customization, automotive brands can innovate and offer advanced features that set their vehicles apart in terms of both aesthetics and functionality.

The Significance of Customization in Automotive Components

Custom automotive injection molding goes beyond standard manufacturing techniques, offering tailored solutions that cater specifically to the unique specifications of each vehicle model. In the automotive sector, every component must endure extreme conditions, including high temperatures, mechanical stress, and exposure to various chemicals. Standard parts often fall short in providing the desired performance, prompting manufacturers to adopt custom solutions designed to optimize strength, flexibility, and environmental resistance. Custom molds are crafted to produce parts with intricate geometries, seamless finishes, and enhanced durability, which are essential for the demanding performance expectations of modern vehicles.

Designing for Superior Performance and Precision

Creating high-performance automotive parts through custom injection molding starts with meticulous design and engineering. Engineers utilize advanced CAD (Computer-Aided Design) software to develop detailed models that optimize material flow, minimize potential defects, and incorporate complex features. Design considerations also include the placement of ribs, bosses, and other reinforcing features to improve structural integrity without adding unnecessary weight. Cooling channels within molds are strategically placed to ensure uniform temperature distribution, which prevents warping and promotes dimensional stability. This sophisticated design process is vital for delivering parts that not only meet precise specifications but also enhance overall vehicle performance.

Cutting-Edge Materials and Manufacturing Techniques

The key to high-performance injection molding lies in selecting the right materials and employing advanced manufacturing processes. Automotive parts subjected to mechanical stress or extreme environmental conditions require materials like reinforced nylons, polycarbonates, or thermoplastic elastomers that provide the necessary strength and heat resistance. Modern manufacturing techniques, including high-precision CNC machining and EDM (Electrical Discharge Machining), facilitate the creation of complex molds with unparalleled accuracy. Surface treatments, such as texturing or coating, are also applied to improve wear resistance and ensure long-lasting performance. These combined efforts result in molds capable of producing components that meet the exacting demands of high-performance vehicles.

Maintaining Quality and Reliability in Production

Consistency is paramount when producing high-performance automotive parts, and quality assurance measures are integral to achieving this goal. Leading manufacturers implement rigorous testing at every stage, from mold fabrication to the final production run. Precision measurement tools and non-destructive testing methods such as 3D scanning and dye penetrant inspections ensure that each mold and resulting part adheres strictly to dimensional and quality standards. Prototype testing and pilot runs help identify and rectify potential issues before full-scale manufacturing. This meticulous quality control process guarantees that every component performs reliably under real-world conditions, reinforcing safety and customer satisfaction.

Innovations Shaping the Future of Injection Molding

As automotive technology evolves, so do the solutions provided by injection molding specialists. The industry is increasingly embracing innovations such as multi-material molding, which allows for the integration of different materials within a single part, improving performance and reducing assembly time. Additive manufacturing techniques are also gaining ground for rapid prototyping and producing complex internal features that traditional methods struggle with. Additionally, smarter mold designs incorporating sensors and automation are helping manufacturers monitor and optimize the molding process in real time. These innovations drive improvements in production efficiency, part quality, and overall vehicle performance, ensuring automakers stay ahead in an increasingly competitive marketplace.

Partnering for Success in High-Performance Automotive Parts

Choosing the right partner for custom automotive injection molding solutions is a strategic decision that can significantly impact a manufacturer’s success. Leading mold makers bring extensive expertise, state-of-the-art technology, and deep knowledge of the automotive industry’s specific needs. Collaborating with experienced manufacturers allows for tailored solutions that address unique design challenges, material selections, and performance requirements. A reliable partner will prioritize quality, innovation, and on-time delivery, providing continuous support throughout the development and production process. In a field where every component contributes to vehicle safety and performance, partnering with a specialized injection molding solution provider ensures that automotive companies can meet their high standards and deliver vehicles that stand out for their reliability and excellence.

In conclusion, custom automotive injection molding solutions are indispensable for achieving high-performance standards in today’s competitive automotive landscape. From innovative design and material selection to rigorous quality control and embracing new manufacturing technologies, these tailored solutions enable automakers to produce parts that excel in durability, functionality, and safety. As automotive engineering continues to push the boundaries of performance and complexity, the importance of customized injection molding solutions will only grow, playing a pivotal role in shaping the future of high-performance vehicles.

Custom Automotive Injection Molding Solutions for High Performance

June 14, 2025 0:46 - no comments yetIn the highly competitive automotive industry, achieving high performance often hinges on the quality and precision of component manufacturing. Custom automotive injection molding solutions are crucial for delivering parts that meet strict safety standards, enhance vehicle durability, and offer superior functional performance. These tailored solutions enable manufacturers to produce complex shapes with tight tolerances, ensuring each part fits precisely and performs reliably throughout the lifespan of the vehicle. By focusing on customization, automotive brands can innovate and offer advanced features that set their vehicles apart in terms of both aesthetics and functionality.

The Significance of Customization in Automotive Components

Custom automotive injection molding goes beyond standard manufacturing techniques, offering tailored solutions that cater specifically to the unique specifications of each vehicle model. In the automotive sector, every component must endure extreme conditions, including high temperatures, mechanical stress, and exposure to various chemicals. Standard parts often fall short in providing the desired performance, prompting manufacturers to adopt custom solutions designed to optimize strength, flexibility, and environmental resistance. Custom molds are crafted to produce parts with intricate geometries, seamless finishes, and enhanced durability, which are essential for the demanding performance expectations of modern vehicles.

Designing for Superior Performance and Precision

Creating high-performance automotive parts through custom injection molding starts with meticulous design and engineering. Engineers utilize advanced CAD (Computer-Aided Design) software to develop detailed models that optimize material flow, minimize potential defects, and incorporate complex features. Design considerations also include the placement of ribs, bosses, and other reinforcing features to improve structural integrity without adding unnecessary weight. Cooling channels within molds are strategically placed to ensure uniform temperature distribution, which prevents warping and promotes dimensional stability. This sophisticated design process is vital for delivering parts that not only meet precise specifications but also enhance overall vehicle performance.

Cutting-Edge Materials and Manufacturing Techniques

The key to high-performance injection molding lies in selecting the right materials and employing advanced manufacturing processes. Automotive parts subjected to mechanical stress or extreme environmental conditions require materials like reinforced nylons, polycarbonates, or thermoplastic elastomers that provide the necessary strength and heat resistance. Modern manufacturing techniques, including high-precision CNC machining and EDM (Electrical Discharge Machining), facilitate the creation of complex molds with unparalleled accuracy. Surface treatments, such as texturing or coating, are also applied to improve wear resistance and ensure long-lasting performance. These combined efforts result in molds capable of producing components that meet the exacting demands of high-performance vehicles.

Maintaining Quality and Reliability in Production

Consistency is paramount when producing high-performance automotive parts, and quality assurance measures are integral to achieving this goal. Leading manufacturers implement rigorous testing at every stage, from mold fabrication to the final production run. Precision measurement tools and non-destructive testing methods such as 3D scanning and dye penetrant inspections ensure that each mold and resulting part adheres strictly to dimensional and quality standards. Prototype testing and pilot runs help identify and rectify potential issues before full-scale manufacturing. This meticulous quality control process guarantees that every component performs reliably under real-world conditions, reinforcing safety and customer satisfaction.

Innovations Shaping the Future of Injection Molding

As automotive technology evolves, so do the solutions provided by injection molding specialists. The industry is increasingly embracing innovations such as multi-material molding, which allows for the integration of different materials within a single part, improving performance and reducing assembly time. Additive manufacturing techniques are also gaining ground for rapid prototyping and producing complex internal features that traditional methods struggle with. Additionally, smarter mold designs incorporating sensors and automation are helping manufacturers monitor and optimize the molding process in real time. These innovations drive improvements in production efficiency, part quality, and overall vehicle performance, ensuring automakers stay ahead in an increasingly competitive marketplace.

Partnering for Success in High-Performance Automotive Parts

Choosing the right partner for custom automotive injection molding solutions is a strategic decision that can significantly impact a manufacturer’s success. Leading mold makers bring extensive expertise, state-of-the-art technology, and deep knowledge of the automotive industry’s specific needs. Collaborating with experienced manufacturers allows for tailored solutions that address unique design challenges, material selections, and performance requirements. A reliable partner will prioritize quality, innovation, and on-time delivery, providing continuous support throughout the development and production process. In a field where every component contributes to vehicle safety and performance, partnering with a specialized injection molding solution provider ensures that automotive companies can meet their high standards and deliver vehicles that stand out for their reliability and excellence.

In conclusion, custom automotive injection molding solutions are indispensable for achieving high-performance standards in today’s competitive automotive landscape. From innovative design and material selection to rigorous quality control and embracing new manufacturing technologies, these tailored solutions enable automakers to produce parts that excel in durability, functionality, and safety. As automotive engineering continues to push the boundaries of performance and complexity, the importance of customized injection molding solutions will only grow, playing a pivotal role in shaping the future of high-performance vehicles.

Innovative Mould Solutions for Small and Large Home Appliances

June 12, 2025 4:24 - no comments yetThe home appliance industry is continuously evolving, driven by consumer demand for smarter, more efficient, and aesthetically pleasing products. At the heart of this evolution lies the development of innovative mould solutions tailored for both small and large appliances. These moulds are designed not only to meet the functional and durability requirements of various appliance components but also to enable manufacturers to optimize production efficiency and product quality. From compact kitchen gadgets to sizable refrigerators, mould technology plays a crucial role in shaping the future of home appliances.

Tailoring Moulds for Small Appliance Components

Small home appliances, such as food processors, electric kettles, and robotic vacuum cleaners, require moulds that can produce intricate, high-precision parts. These components often feature complex geometries and demand tight tolerances to ensure seamless assembly and reliable operation. Innovative mould solutions for small appliances incorporate advanced design software and simulation tools to optimize plastic flow and cooling, reducing defects like warping or shrinkage. Additionally, rapid prototyping techniques allow manufacturers to test and refine mould designs quickly, accelerating product development cycles without compromising quality.

Large-Scale Moulding for Bigger Appliances

Large home appliances, including refrigerators, washing machines, and air conditioning units, present unique challenges in mould design and manufacturing. The moulds for these appliances must accommodate bigger parts with thicker walls, which require careful control of cooling rates and material flow to prevent internal stresses and deformation. Innovations in large-size moulding include the use of high-precision CNC machining and modular mould designs that facilitate maintenance and scalability. These solutions help manufacturers produce robust, durable components capable of withstanding the demands of everyday household use.

Multi-Material Moulding: Enhancing Functionality and Design

One of the most exciting advancements in mould technology is multi-material moulding, which allows the integration of different plastics or materials within a single component. This technique is particularly beneficial for home appliances, enabling the combination of rigid and flexible parts, or incorporating soft-touch surfaces directly into hard plastic housings. Multi-material moulding not only improves the functionality and ergonomics of appliances but also reduces assembly steps and production costs. By using this approach, manufacturers can create innovative designs that enhance user experience while maintaining manufacturing efficiency.

Sustainable Moulding Practices for Eco-Friendly Appliances

With increasing environmental awareness, the home appliance mould industry is embracing sustainable manufacturing practices, and mould technology is no exception. Innovative mould solutions now focus on reducing material waste through optimized design and precision manufacturing. Techniques such as in-mold decoration (IMD) allow for the integration of decorative surfaces during the moulding process, eliminating the need for additional painting or coating steps and reducing chemical usage. Moreover, the use of recycled plastics in moulding processes is becoming more prevalent, supported by mould designs that accommodate the unique properties of these materials without sacrificing quality.

Quality Control and Precision Engineering

Ensuring consistent quality in both small and large appliance components requires meticulous quality control throughout the moulding process. Advanced inspection technologies, including 3D scanning and mold flow analysis, help detect potential defects early and verify that parts meet strict dimensional and performance standards. Precision engineering in mould fabrication, supported by computer numerical control (CNC) machining and electrical discharge machining (EDM), guarantees moulds with tight tolerances and smooth finishes. This attention to detail ensures that every appliance component produced contributes to the overall reliability and longevity of the final product.

Accelerating Time-to-Market with Prototyping and Testing

Speed is a critical factor in today’s competitive appliance market. Innovative mould solutions incorporate rapid prototyping and iterative testing to shorten development timelines. High-resolution 3D printing enables the creation of functional prototypes that closely mimic production parts, allowing designers and engineers to validate form, fit, and function before final mould fabrication. This iterative approach reduces costly revisions and ensures that moulds are optimized for mass production from the outset, helping manufacturers bring new appliances to market faster.

The Future of Home Appliance Moulding

Looking ahead, the integration of digital manufacturing technologies and smart moulding systems will further transform home appliance production. Industry 4.0 advancements, such as real-time monitoring and predictive maintenance of moulds, will enhance production efficiency and reduce downtime. Additionally, ongoing research into novel materials and moulding techniques promises to expand design possibilities and improve sustainability. As manufacturers continue to innovate, mould solutions will remain at the forefront, enabling the creation of smarter, more durable, and environmentally responsible home appliances that meet the evolving needs of consumers worldwide.

In conclusion, innovative mould solutions are essential for producing high-quality components across the spectrum of home appliances, from small gadgets to large machines. By embracing advanced design, multi-material capabilities, sustainability, and precision engineering, the industry is well-positioned to deliver appliances that combine functionality, style, and durability in an increasingly competitive market.

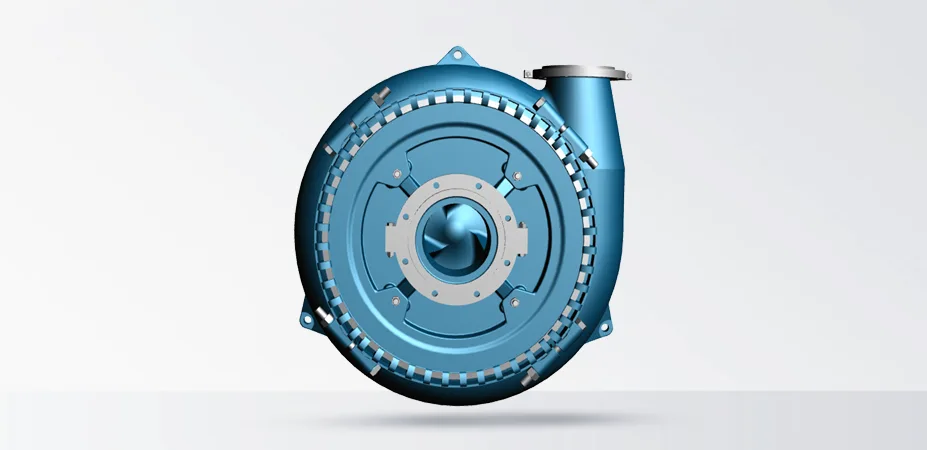

The Manufacturing Excellence Behind CNSME Pump’s Centrifugal Slurry Pumps

June 12, 2025 2:39 - no comments yetManufacturing excellence is the cornerstone of any successful industrial product, and CNSME Pump’s centrifugal slurry pumps stand as a testament to this principle. These pumps are globally recognized for their exceptional performance, durability, and reliability, which are the direct result of a meticulous manufacturing process rooted in advanced technology, rigorous quality control, and innovative design. From raw material selection to final assembly, every step in CNSME’s manufacturing process is carefully executed to ensure that each slurry pump delivers superior performance in the most demanding operating environments, making them trusted solutions across industries such as mining, chemical processing, and power generation.

Cutting-Edge Manufacturing Technologies

At the heart of CNSME’s manufacturing excellence lies the adoption of cutting-edge production technologies. The company utilizes computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to create highly precise and optimized pump components. These digital tools allow for detailed simulations and fine-tuning of every part before physical production begins, ensuring that each component meets exact specifications. Advanced casting and forging techniques are employed to produce durable, high-quality components such as impellers, casings, and shafts, which are vital for withstanding extreme wear and corrosion. The integration of automation and robotic welding further enhances consistency and precision, reducing human errors and ensuring that every pump leaving the production line adheres to strict quality standards.

Rigorous Quality Control and Testing Protocols

CNSME’s commitment to manufacturing excellence is reflected in its rigorous quality control and testing protocols. Every pump component undergoes a series of inspections, including dimensional verification, metallurgical analysis, and surface testing, to guarantee consistency and reliability. Complete assemblies are subjected to dynamic balancing, pressure testing, and hydraulic performance evaluations before they are shipped. This extensive testing process ensures that each pump can operate under high-stress conditions without failure. Additionally, CNSME invests in environmental testing facilities to simulate operational environments, such as high temperature, corrosive atmospheres, and abrasive conditions, verifying that pumps can perform reliably in the toughest scenarios. This thorough quality assurance process instills confidence that every manufactured pump meets or exceeds industry standards.

Emphasis on Material Science and Innovation

The durability and longevity of CNSME’s centrifugal slurry pump stem from their careful selection of materials and continuous innovation in material science. The company sources high-quality alloys, ceramics, and specialized composites known for their exceptional resistance to wear, corrosion, and impact. These materials are vital to ensuring that pump components like impellers and liners can withstand the rigors of handling abrasive and chemically aggressive slurries. CNSME constantly explores new material compositions and surface treatments to improve performance and extend service intervals. Their dedication to research and development in material science allows them to create pumps that not only perform better but also operate more sustainably, with reduced material fatigue and longer lifespan.

Skilled Workforce and Precision Assembly

Manufacturing excellence also depends heavily on the skill and dedication of the workforce responsible for assembling the pumps. CNSME prides itself on employing highly trained technicians and engineers who are experts in precision assembly. Every component is carefully integrated using advanced assembly techniques that ensure perfect alignment and balance—crucial factors for minimizing vibrations, reducing wear, and enhancing overall operational stability. The company emphasizes continuous training programs to keep staff updated with the latest manufacturing methods and safety protocols. During assembly, strict adherence to standard operating procedures and quality benchmarks guarantees that each pump not only meets design specifications but also embodies the highest standards of craftsmanship that CNSME is known for.

Sustainable Manufacturing Practices

CNSME’s manufacturing processes are designed to be environmentally responsible and sustainable. The company implements energy-efficient techniques, such as waste heat recovery and optimized machining processes, to reduce its carbon footprint. Recycling of scrap materials, eco-friendly surface treatments, and environmentally safe coatings are integral to their manufacturing philosophy. These sustainable practices ensure that while CNSME produces high-performance pumps, it also minimizes environmental impact—aligning with global standards for industrial sustainability. This commitment reflects a broader vision of manufacturing that balances operational excellence with ecological responsibility, providing clients with solutions that are not only reliable but also environmentally conscious.

Continuous Improvement and Innovation

The manufacturing excellence behind CNSME’s pumps is driven by a culture of continuous improvement and innovation. The company constantly evaluates and upgrades its manufacturing processes, integrating new technologies and industry best practices. Feedback from customers, field performance data, and ongoing research inform their development strategies, enabling CNSME to deliver pumps that incorporate the latest advances in hydraulics, materials, and manufacturing methods. This proactive approach ensures that their slurry pumps remain at the forefront of industry standards, providing clients with durable and efficient solutions that are tailored to their evolving needs. CNSME’s dedication to excellence ensures that each pump is a product of not only advanced manufacturing but also relentless innovation.