The Importance of Temperature Control in Masterbatch Extrusion

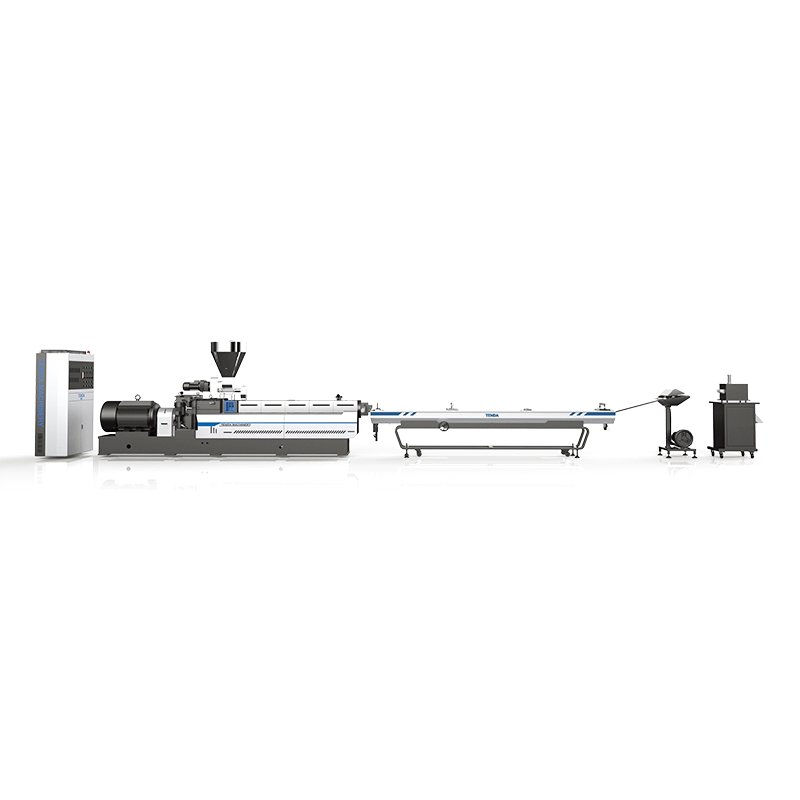

28 de Outubro de 2024, 13:25 - sem comentários ainda | Ninguém está seguindo este artigo ainda.Temperature control plays a crucial role in the masterbatch extrusion process. Masterbatch is a concentrated mixture of pigments and additives that are used to color plastics. The extrusion process involves melting and mixing these components to create a uniform product. Maintaining the right temperature is essential to ensure that the materials flow properly and achieve the desired quality.

Effects of Temperature on Material Properties

The properties of the materials used in masterbatch extruder are significantly affected by temperature. High temperatures can lead to degradation of the polymer, resulting in a loss of mechanical properties and color strength. Conversely, low temperatures may cause incomplete melting and poor dispersion of pigments. Therefore, it is vital to monitor and control the temperature throughout the extrusion process to maintain the integrity of the materials.

Temperature Zones in Extrusion

In the extrusion process, there are several temperature zones that need to be carefully managed. These include the feed zone, transition zone, and metering zone. Each zone has a specific temperature requirement to facilitate the melting and mixing of materials. Proper temperature management in each zone ensures that the masterbatch is produced consistently and meets quality standards.

Impact on Extrusion Speed

Temperature control also influences the speed of the extrusion process. Higher temperatures typically allow for faster extrusion rates, as the materials flow more easily. However, if the temperature exceeds the optimal range, it can lead to issues such as material degradation and increased wear on the equipment. Therefore, finding the right balance between temperature and extrusion speed is essential for efficient production.

Quality of Final Product

The quality of the final masterbatch product is directly linked to temperature control during extrusion. Inconsistent temperatures can result in variations in color, texture, and performance of the masterbatch. This inconsistency can lead to defects in the final plastic products, affecting their appearance and functionality. By maintaining stable temperatures, manufacturers can ensure a high-quality end product.

Energy Efficiency Considerations

Effective temperature control can also contribute to energy efficiency in the extrusion process. By optimizing the heating and cooling systems, manufacturers can reduce energy consumption while maintaining product quality. This not only lowers production costs but also minimizes the environmental impact of the manufacturing process.

Monitoring Temperature in Real-Time

Advancements in technology have made it possible to monitor temperature in real-time during the extrusion process. Using sensors and automated systems, manufacturers can track temperature changes and make adjustments as needed. This real-time monitoring helps to maintain consistent quality and reduces the risk of production errors.

Training and Best Practices

Proper training for operators is essential to ensure effective temperature control in masterbatch extrusion. Operators should be familiar with the equipment and understand the importance of maintaining the correct temperatures. Implementing best practices, such as regular maintenance of temperature control systems, can further enhance the quality of the extrusion process.

Challenges in Temperature Control

Despite the importance of temperature control, challenges can arise during the extrusion process. Variations in raw material properties, equipment malfunctions, and environmental factors can all impact temperature stability. Manufacturers must be prepared to address these challenges to maintain consistent quality in their masterbatch production.

Future Trends in Temperature Control

As technology continues to evolve, new methods for temperature control in extrusion are being developed. Innovations such as advanced heating systems and predictive analytics are being explored to enhance temperature management. These trends promise to improve the efficiency and quality of masterbatch extrusion processes in the future.

0sem comentários ainda

Por favor digite as duas palavras abaixo