Whole melt extracts are a popular choice for vape disposables due to their high potency and flavorful profile. This type of extract is made using a process that involves freezing fresh cannabis buds and then extracting the trichomes to create a concentrated product that is rich in cannabinoids and terpenes.

Harvesting and Freezing Fresh Cannabis Buds

The first step in the extraction process is to harvest fresh cannabis buds at peak ripeness. Once the buds are collected, they are immediately frozen to preserve their trichomes and terpenes. Freezing the buds helps to prevent any degradation of the cannabinoids and ensures a high-quality product.

Extraction Methods for Whole Melt Extracts

After the buds have been frozen, they are then processed using a variety of methods such as cold water extraction, dry sift, or ice wax extraction. These methods involve sifting or washing the frozen buds to separate the trichomes from the plant material. The resulting product is a fine powder or resin that is rich in cannabinoids and terpenes.

Drying and Curing the Extract

Once the trichomes have been extracted, they are then dried and cured to remove any excess moisture and to enhance the flavor profile of the extract. This drying and curing process can take anywhere from a few days to a few weeks, depending on the desired consistency and flavor of the extract.

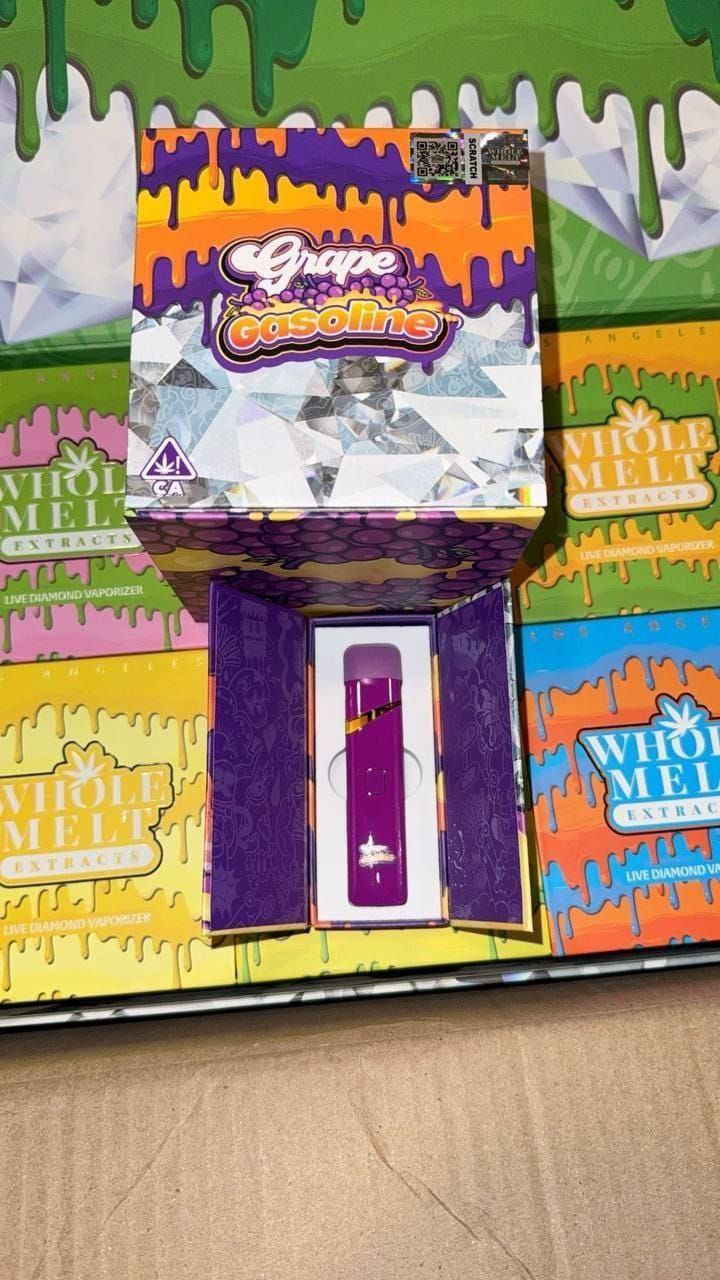

Packaging and Consumption

After the drying and curing process is complete, the whole melt extract is then packaged into vape disposables for easy consumption. These disposables are typically filled with a measured amount of whole melt extract, allowing for easy and convenient use on the go.

Benefits and Precautions of Whole Melt Extracts

Whole melt extracts are known for their high potency and flavorful profile, making them a popular choice for cannabis enthusiasts looking for a strong and enjoyable vaping experience. The extraction process used to create whole melt extracts ensures a high-quality product that is rich in cannabinoids and terpenes, providing users with a potent and flavorful vaping experience.

Tips for First-Time Users

For first-time users of whole melt disposables , it is important to start with a low dose and gradually increase as needed. This will allow you to gauge your tolerance and find the right dosage for your needs. Additionally, be sure to store your disposables in a cool, dark place to preserve the potency and flavor of the extract.

Conclusion

Overall, exploring the extraction process of whole melt extracts for disposables provides valuable insight into the production of these high-quality products . By understanding how whole melt extracts are made, you can better appreciate the craftsmanship and care that goes into creating these potent and flavorful vaping options. So, next time you reach for a whole melt disposable, you can vape with confidence knowing that you are enjoying a premium product that has been carefully crafted to deliver a top-notch vaping experience.

Evaluating the Efficacy of Popular Stress Management Books

October 29, 2024 2:37 - no comments yetstress management techniques is a crucial aspect of maintaining mental health and well-being. Many individuals turn to books for guidance on how to manage stress effectively. This article evaluates the efficacy of popular stress management books, exploring their approaches, techniques, and overall effectiveness in helping readers cope with stress.

The Importance of Stress Management Books

Stress management books provide valuable insights and strategies for dealing with stress. They often offer a range of techniques, from mindfulness practices to cognitive behavioral strategies. These books can serve as a resource for individuals seeking to understand their stressors and learn how to manage them. By reading these books, individuals can gain new perspectives on their challenges.

Popular Titles in Stress Management

Several popular titles have gained recognition for their approaches to stress management. Books such as “The Relaxation Response” by Herbert Benson, “The Stress Solution” by Arthur E. Schwartz, and “The Mindful Way Through Stress” by Shamash Alidina are among the most recommended. Each of these books presents unique methods for managing stress, making them valuable resources for readers.

Evaluating “The Relaxation Response”

Herbert Benson’s “The Relaxation Response” emphasizes the importance of relaxation techniques in reducing stress. The book introduces readers to simple practices such as deep breathing and meditation. Many readers have found these techniques effective in promoting relaxation and reducing anxiety. The book’s scientific approach, supported by research, adds to its credibility and effectiveness.

Assessing “The Stress Solution”

Arthur E. Schwartz’s “The Stress Solution” focuses on practical strategies for managing stress in everyday life. The book offers actionable steps that readers can implement immediately. Schwartz combines personal anecdotes with research findings, making the content relatable and engaging. Readers appreciate the straightforward approach and the emphasis on real-life applications.

Exploring “The Mindful Way Through Stress”

Shamash Alidina’s “The Mindful Way Through Stress” introduces mindfulness as a key strategy for stress management. The book provides readers with mindfulness exercises and techniques to cultivate awareness and presence. Many readers report significant improvements in their ability to cope with stress after practicing the techniques outlined in the book. The emphasis on mindfulness resonates with those seeking a holistic approach to stress management.

Comparing Different Approaches

Each of these popular stress management books offers a unique approach to handling stress. While “The Relaxation Response” emphasizes relaxation techniques, “The Stress Solution” focuses on practical strategies. “The Mindful Way Through Stress” highlights the importance of mindfulness. Readers may find that different approaches resonate with them based on their personal preferences and experiences.

Reader Testimonials and Success Stories

Many readers have shared their success stories after implementing the techniques from these books. Testimonials often highlight how these strategies have led to reduced anxiety, improved focus, and a greater sense of calm. Readers appreciate the practical nature of the advice provided, which allows them to apply the concepts in their daily lives. These success stories serve as a testament to the efficacy of the books.

Limitations of Stress Management Books

While stress management books can be beneficial, they may not be suitable for everyone. Some individuals may require personalized support from a mental health professional. Additionally, the effectiveness of the techniques may vary based on individual circumstances. It is essential for readers to recognize their unique needs and seek additional help if necessary.

Integrating Techniques into Daily Life

To maximize the benefits of stress management books, readers should integrate the techniques into their daily routines. Consistency is key when practicing relaxation, mindfulness, or other strategies. Setting aside time each day to practice these techniques can lead to long-term benefits. Readers are encouraged to experiment with different methods to find what works best for them.

The Role of Professional Guidance

While self-help books provide valuable insights, professional guidance can enhance the effectiveness of stress management strategies. Therapists and counselors can offer personalized support and help individuals navigate their stressors more effectively. Combining the knowledge gained from books with professional guidance can lead to a more comprehensive approach to stress management.

Conclusion: The Value of Stress Management Books

In conclusion, popular stress management books offer valuable resources for individuals seeking to cope with stress. Titles like “The Relaxation Response,” “The Stress Solution,” and “The Mindful Way Through Stress” provide effective techniques and strategies. While these books can be beneficial, it is important for readers to recognize their unique needs and seek additional support when necessary. By integrating the techniques into daily life and considering professional guidance, individuals can enhance their stress management journey

The Benefits of Cognitive-Behavioral Techniques in Managing Stress

October 29, 2024 2:21 - no comments yetCognitive-Behavioral Techniques (CBT) are widely recognized for their effectiveness in managing stress and improving mental health. These techniques focus on the relationship between thoughts, feelings, and behaviors. By identifying and changing negative thought patterns, individuals can reduce stress and enhance their overall well-being. CBT provides practical tools that can be applied in everyday life to cope with stress more effectively.

Understanding Stress and Its Impact

Stress is a stress management for beginners response to challenging situations. It can arise from various sources, including work, relationships, and personal challenges. While some stress can be motivating, excessive stress can lead to negative physical and emotional consequences. Chronic stress can contribute to anxiety, depression, and other health issues. Therefore, finding effective strategies to manage stress is essential for maintaining a healthy lifestyle.

The Role of Cognitive-Behavioral Techniques

Cognitive-Behavioral Techniques play a crucial role in stress management by helping individuals recognize and modify unhelpful thought patterns. These techniques encourage individuals to challenge negative beliefs and replace them with more positive and realistic thoughts. By doing so, individuals can change their emotional responses to stressors and develop healthier coping mechanisms.

Identifying Negative Thought Patterns

One of the first steps in using CBT for stress management is identifying negative thought patterns. Common cognitive distortions include all-or-nothing thinking, overgeneralization, and catastrophizing. By becoming aware of these patterns, individuals can begin to challenge and reframe their thoughts. This process allows for a more balanced perspective and reduces the intensity of stress responses.

Challenging Negative Thoughts

Once negative thought patterns are identified, the next step is to challenge them. Individuals can ask themselves questions such as "Is this thought based on facts?" or "What evidence do I have to support this belief?" This questioning technique helps individuals evaluate the validity of their thoughts and encourages them to consider alternative viewpoints. By challenging negative thoughts, individuals can reduce their emotional distress and manage stress more effectively.

Developing Positive Coping Strategies

Cognitive-Behavioral Techniques also emphasize the importance of developing positive coping strategies. These strategies can include problem-solving skills, relaxation techniques, and time management skills. By equipping individuals with practical tools, CBT empowers them to take control of their stressors. For example, learning relaxation techniques such as deep breathing or progressive muscle relaxation can help individuals calm their minds and bodies during stressful situations.

Setting Realistic Goals

Setting realistic goals is another essential aspect of managing stress through CBT. Individuals can break down larger tasks into smaller, manageable steps. This approach reduces feelings of overwhelm and allows individuals to focus on one step at a time. By achieving small goals, individuals can build confidence and a sense of accomplishment, which can further reduce stress levels.

Practicing Mindfulness

Mindfulness is a key component of many Cognitive-Behavioral Techniques. It involves being present in the moment and observing thoughts and feelings without judgment. Mindfulness practices, such as meditation and mindful breathing, can help individuals develop greater awareness of their stress triggers. By practicing mindfulness, individuals can learn to respond to stressors with greater calm and clarity.

The Importance of Self-Compassion

Self-compassion is an essential element in managing stress through CBT. Individuals are encouraged to treat themselves with kindness and understanding, especially during challenging times. Recognizing that everyone experiences stress and setbacks can help individuals develop a more compassionate attitude toward themselves. This self-compassion can reduce feelings of guilt and shame, allowing for a healthier emotional response to stress.

Seeking Professional Support

While Cognitive-Behavioral Techniques can be practiced independently, seeking professional support can enhance their effectiveness. Therapists trained in CBT can provide guidance and support in implementing these techniques. They can help individuals navigate complex emotions and develop personalized strategies for managing stress. Professional support can also offer accountability and encouragement throughout the process.

Conclusion: Embracing Cognitive-Behavioral Techniques for Stress Management

In conclusion, Cognitive-Behavioral Techniques offer valuable tools for managing stress and improving mental health. By identifying and challenging negative thought patterns, individuals can develop healthier coping strategies and reduce their stress levels. Incorporating mindfulness and self-compassion into the practice can further enhance its effectiveness. Embracing these techniques can lead to a more balanced and fulfilling life, free from the overwhelming effects of stress

The Importance of Temperature Control in Masterbatch Extrusion

October 28, 2024 13:25 - no comments yetTemperature control plays a crucial role in the masterbatch extrusion process. Masterbatch is a concentrated mixture of pigments and additives that are used to color plastics. The extrusion process involves melting and mixing these components to create a uniform product. Maintaining the right temperature is essential to ensure that the materials flow properly and achieve the desired quality.

Effects of Temperature on Material Properties

The properties of the materials used in masterbatch extruder are significantly affected by temperature. High temperatures can lead to degradation of the polymer, resulting in a loss of mechanical properties and color strength. Conversely, low temperatures may cause incomplete melting and poor dispersion of pigments. Therefore, it is vital to monitor and control the temperature throughout the extrusion process to maintain the integrity of the materials.

Temperature Zones in Extrusion

In the extrusion process, there are several temperature zones that need to be carefully managed. These include the feed zone, transition zone, and metering zone. Each zone has a specific temperature requirement to facilitate the melting and mixing of materials. Proper temperature management in each zone ensures that the masterbatch is produced consistently and meets quality standards.

Impact on Extrusion Speed

Temperature control also influences the speed of the extrusion process. Higher temperatures typically allow for faster extrusion rates, as the materials flow more easily. However, if the temperature exceeds the optimal range, it can lead to issues such as material degradation and increased wear on the equipment. Therefore, finding the right balance between temperature and extrusion speed is essential for efficient production.

Quality of Final Product

The quality of the final masterbatch product is directly linked to temperature control during extrusion. Inconsistent temperatures can result in variations in color, texture, and performance of the masterbatch. This inconsistency can lead to defects in the final plastic products, affecting their appearance and functionality. By maintaining stable temperatures, manufacturers can ensure a high-quality end product.

Energy Efficiency Considerations

Effective temperature control can also contribute to energy efficiency in the extrusion process. By optimizing the heating and cooling systems, manufacturers can reduce energy consumption while maintaining product quality. This not only lowers production costs but also minimizes the environmental impact of the manufacturing process.

Monitoring Temperature in Real-Time

Advancements in technology have made it possible to monitor temperature in real-time during the extrusion process. Using sensors and automated systems, manufacturers can track temperature changes and make adjustments as needed. This real-time monitoring helps to maintain consistent quality and reduces the risk of production errors.

Training and Best Practices

Proper training for operators is essential to ensure effective temperature control in masterbatch extrusion. Operators should be familiar with the equipment and understand the importance of maintaining the correct temperatures. Implementing best practices, such as regular maintenance of temperature control systems, can further enhance the quality of the extrusion process.

Challenges in Temperature Control

Despite the importance of temperature control, challenges can arise during the extrusion process. Variations in raw material properties, equipment malfunctions, and environmental factors can all impact temperature stability. Manufacturers must be prepared to address these challenges to maintain consistent quality in their masterbatch production.

Future Trends in Temperature Control

As technology continues to evolve, new methods for temperature control in extrusion are being developed. Innovations such as advanced heating systems and predictive analytics are being explored to enhance temperature management. These trends promise to improve the efficiency and quality of masterbatch extrusion processes in the future.

How Masterbatch Extruders Improve Polymer Processing Efficiency

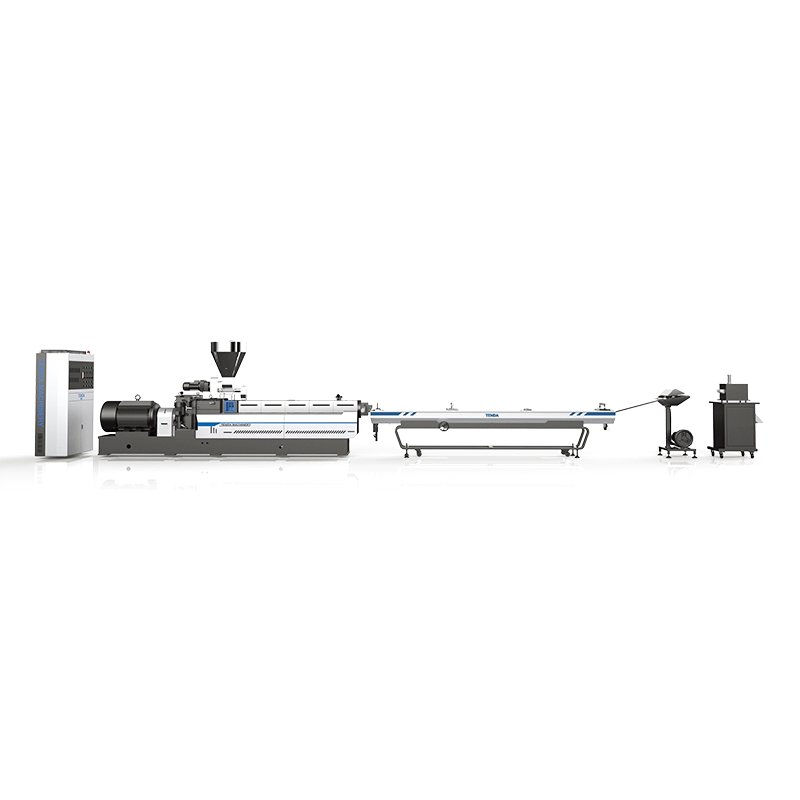

October 28, 2024 11:47 - no comments yetmasterbatch extruder are specialized machines used in the polymer processing industry. They play a crucial role in the production of plastic products by allowing the incorporation of additives, colors, and other materials into a polymer base. The efficiency of these extruders significantly impacts the overall productivity and quality of the final products. Understanding how masterbatch extruders work can provide insights into their importance in polymer processing.

The Role of Masterbatch in Polymer Processing

Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin. It is used to color and enhance the properties of plastics during the extrusion process. By using masterbatch, manufacturers can achieve consistent color and performance in their products. This method is preferred over direct addition of pigments because it allows for better dispersion and reduces the risk of contamination.

Advantages of Using Masterbatch Extruders

One of the primary advantages of masterbatch extruders is their ability to improve processing efficiency. These machines ensure that the masterbatch is evenly distributed throughout the polymer matrix. This uniformity leads to better mechanical properties and aesthetics in the final product. Additionally, masterbatch extruders can handle a wide range of materials, making them versatile for various applications.

Enhanced Mixing Capabilities

Masterbatch extruders are designed with advanced mixing capabilities. They utilize various screw designs and configurations to achieve optimal mixing of the masterbatch with the polymer. This enhanced mixing ensures that the additives are thoroughly integrated, resulting in improved product quality. The ability to customize the mixing process also allows manufacturers to tailor the properties of the final product to meet specific requirements.

Improved Production Rates

Another significant benefit of masterbatch extruders is their ability to increase production rates. These machines can process large volumes of material quickly, reducing the time required for production. The efficient mixing and processing capabilities of masterbatch extruders enable manufacturers to produce more products in less time, leading to higher output and profitability.

Energy Efficiency in Polymer Processing

Energy consumption is a critical factor in polymer processing. Masterbatch extruders are designed to operate efficiently, minimizing energy usage while maximizing output. By optimizing the processing parameters, manufacturers can reduce energy costs and improve the overall sustainability of their operations. This energy efficiency is essential in today’s environmentally conscious market.

Quality Control and Consistency

Quality control is vital in the polymer processing industry. Masterbatch extruders contribute to maintaining high-quality standards by ensuring consistent mixing and processing. The use of masterbatch allows for precise control over the color and properties of the final product. This consistency is crucial for manufacturers who need to meet strict regulatory requirements and customer expectations.

Flexibility in Formulation

Masterbatch extruders offer flexibility in formulation, allowing manufacturers to experiment with different additives and colors. This flexibility enables the development of innovative products that can meet specific market demands. By adjusting the formulation, manufacturers can create unique products that stand out in a competitive market.

Cost-Effectiveness of Masterbatch Extruders

Investing in masterbatch extruders can be cost-effective for manufacturers. While the initial investment may be significant, the long-term benefits in terms of increased production efficiency and reduced waste can lead to substantial cost savings. Additionally, the ability to produce high-quality products can enhance a manufacturer’s reputation and customer loyalty.

Conclusion

In conclusion, masterbatch extruders play a vital role in improving polymer processing efficiency. Their advanced mixing capabilities, increased production rates, and energy efficiency make them essential tools in the plastic manufacturing industry. By utilizing masterbatch extruders, manufacturers can achieve consistent quality, flexibility in formulation, and cost-effectiveness. As the demand for high-quality plastic products continues to grow, the importance of masterbatch extruders in polymer processing will only increase

Advantages of Single Screw Extruders Over Other Types

October 27, 2024 15:40 - no comments yetsingle screw extruder manufacturer have established themselves as a preferred choice in the plastic processing industry. While various types of extruders exist, single screw extruders offer unique advantages that make them particularly appealing for manufacturers. Understanding these benefits is crucial for companies looking to optimize their production processes.

Simplicity in Design

One of the primary advantages of single screw extruders is their simpler design compared to other types, such as twin screw extruders. The straightforward construction results in fewer components, which translates to lower maintenance costs and easier operation. This simplicity makes them ideal for manufacturers who may not have extensive technical expertise, allowing for quick setup and operation.

Cost-Effectiveness

Single screw extruders are generally more cost-effective than their counterparts. The initial investment is often lower, and the reduced complexity means that repair and maintenance costs are minimized. Additionally, their energy-efficient operation contributes to lower overall production costs. This cost-effectiveness makes single screw extruders an attractive option for businesses aiming to maximize profitability.

Energy Efficiency

In terms of energy consumption, single screw extruders often outperform other types. Their design allows for effective melting and processing of plastics with lower energy input. This efficiency not only reduces operational costs but also minimizes the environmental impact of production. As sustainability becomes increasingly important in manufacturing, the energy efficiency of single screw extruders is a significant advantage.

Versatility in Material Processing

Single screw extruders are known for their versatility in processing a wide range of materials. They can handle various plastics, including polyethylene, polypropylene, and polystyrene, making them adaptable for different applications. This flexibility allows manufacturers to switch between products without needing extensive modifications to the equipment. Such versatility is particularly beneficial in industries with rapidly changing demands.

Consistent Output Quality

Another key advantage of single screw extruders is their ability to produce high-quality, consistent outputs. The design of the screw and barrel allows for uniform melting and mixing, which is essential for maintaining product quality. This consistency is vital in industries like packaging, where uniformity is critical for consumer satisfaction. Reliable output quality helps manufacturers maintain their reputation and meet regulatory standards.

Ease of Operation and Control

Single screw extruders are relatively easy to operate and control. Operators can quickly learn to manage the machine, making it accessible to a broader range of personnel. The process control systems in modern single screw extruders allow for precise adjustments to temperature, pressure, and feed rates. This level of control enhances the overall efficiency of the production process and reduces the likelihood of defects.

Lower Maintenance Requirements

The simpler design of single screw extruders leads to lower maintenance requirements compared to more complex systems. Fewer moving parts mean there is less that can go wrong, resulting in reduced downtime for repairs. Regular maintenance tasks are also easier to perform, allowing operators to keep the machines in optimal condition with minimal effort. This reliability is crucial for maintaining production schedules and minimizing disruptions.

Applications Across Various Industries

Single screw extruders find applications across multiple industries, including packaging, automotive, and consumer goods. Their versatility allows manufacturers to produce a wide range of products, from films and sheets to intricate components. This broad applicability enhances their appeal, as companies can utilize a single type of extruder for various production needs.

Conclusion

In conclusion, single screw extruders offer numerous advantages over other types, including simpler design, cost-effectiveness, energy efficiency, and versatility. Their ability to produce consistent output quality and ease of operation makes them a preferred choice for many manufacturers. As the industry continues to evolve, the benefits of single screw extruders will remain crucial for companies looking to optimize their production processes and meet the demands of a competitive market