High-Efficiency Ductwork Cutting Machine for Professional Fabrication

September 4, 2024 15:27 - no comments yet | No one following this article yet. When it comes to HVAC installations, precision is key. Every cut in the ductwork needs to be accurate to ensure optimal airflow and energy efficiency. That's where a high-efficiency ductwork cutting machine comes into play. Advantages of High-Efficiency Ductwork Cutting Machines These cutting machines are designed specifically for professional fabrication, giving HVAC technicians the ability ...

When it comes to HVAC installations, precision is key. Every cut in the ductwork needs to be accurate to ensure optimal airflow and energy efficiency. That's where a high-efficiency ductwork cutting machine comes into play. Advantages of High-Efficiency Ductwork Cutting Machines These cutting machines are designed specifically for professional fabrication, giving HVAC technicians the ability ...

When it comes to HVAC installations, precision is key. Every cut in the ductwork needs to be accurate to ensure optimal airflow and energy efficiency. That's where a high-efficiency ductwork cutting machine comes into play.

Advantages of High-Efficiency Ductwork Cutting Machines

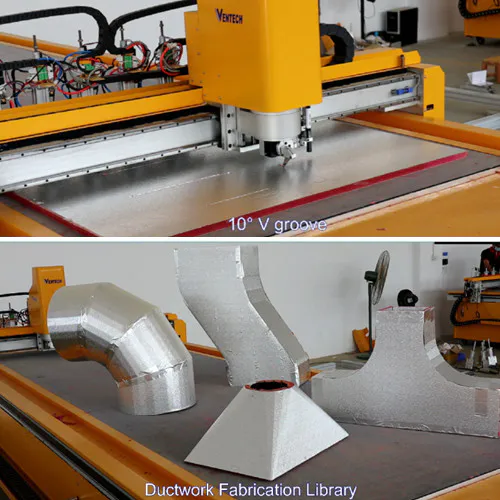

These cutting machines are designed specifically for professional fabrication, giving HVAC technicians the ability to create precise cuts quickly and easily. With advanced technology and user-friendly features, these machines are revolutionizing the way ductwork is fabricated.

Time and Labor Savings

One of the key benefits of using a high-efficiency ductwork cutting machine is the time and labor savings it provides. With traditional methods of cutting ductwork, technicians would have to measure, mark, and then manually cut each piece, which could be time-consuming and prone to human error. With a cutting machine, technicians can simply input the specifications and let the machine do the work, resulting in faster and more accurate cuts.

Consistency and Accuracy

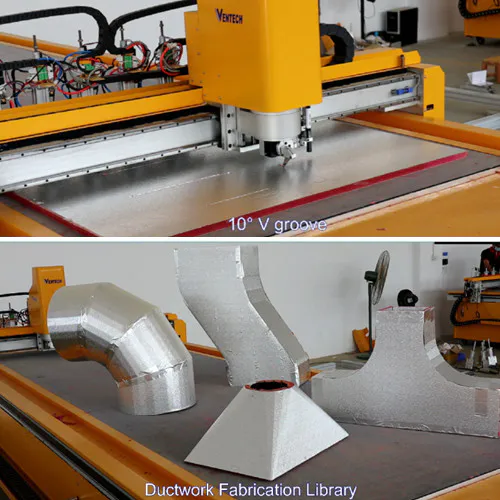

Another advantage of using a cutting machine is the consistency it provides. When cutting ductwork manually, slight variations in measurements or cuts can lead to inefficiencies in the HVAC system. A cutting machine ensures that each piece is cut to the exact specifications every time, guaranteeing a perfect fit and optimal performance.

Enhanced Safety

In addition to accuracy and time savings, cutting machines also offer a higher level of safety for technicians. Traditional methods of cutting ductwork can be hazardous, requiring sharp tools and repetitive motions that can lead to injuries. Cutting machines eliminate these risks by automating the cutting process, reducing the chance of accidents and ensuring a safer work environment.

Customization and Flexibility

Furthermore, cutting machines allow for greater customization and flexibility in ductwork fabrication. With the ability to program specific measurements and angles, technicians can easily create unique designs that meet the needs of any HVAC system. This versatility allows for more efficient installations and better overall performance.

Conclusion

Overall, a high-efficiency ductwork cutting machine is a valuable tool for professional fabrication in the HVAC industry. By providing accurate cuts, time savings, consistency, safety, and customization, these machines are revolutionizing the way ductwork is fabricated and installed. Whether you're a seasoned technician or just starting out in the industry, investing in a cutting machine can help you take your HVAC installations to the next level.

0no comments yet

Please type the two words below