CNSME Pump: Innovative Features in Modern Gravel Pump Design

11 de Junho de 2025, 3:50 - sem comentários ainda | Ninguém está seguindo este artigo ainda.CNSME has set a new standard in gravel pump manufacturing by prioritizing the use of high chrome alloys and wear-resistant rubber throughout their product lines. These materials are chosen specifically to combat the intense abrasion and corrosion that occur during the transport of sand, gravel, and slurry. The result is a pump that not only lasts longer but also maintains high efficiency over its operational life, reducing both maintenance frequency and replacement costs for operators in construction, mining, and dredging industries.

Precision Manufacturing with Cutting-Edge Technology

To ensure each pump meets the rigorous demands of modern applications, CNSME has invested in imported advanced machinery and optimized production processes. This precision manufacturing approach guarantees that every component is built to exacting standards, resulting in pumps that deliver consistent performance even under severe duty conditions. The attention to detail in production also allows for tighter tolerances, which improves hydraulic efficiency and reduces the risk of leaks or premature wear.

Real-Time Monitoring and Data-Logging

One of the most forward-thinking features in CNSME’s modern gravel pump design is the integration of real-time monitoring and data-logging systems. Operators can now track pump performance, flow rates, and wear patterns as the equipment runs. This capability enables predictive maintenance, allowing issues to be addressed before they become critical failures. The result is less unplanned downtime, more efficient operations, and a longer lifespan for each pump, which is especially valuable for large-scale dredging and material handling projects.

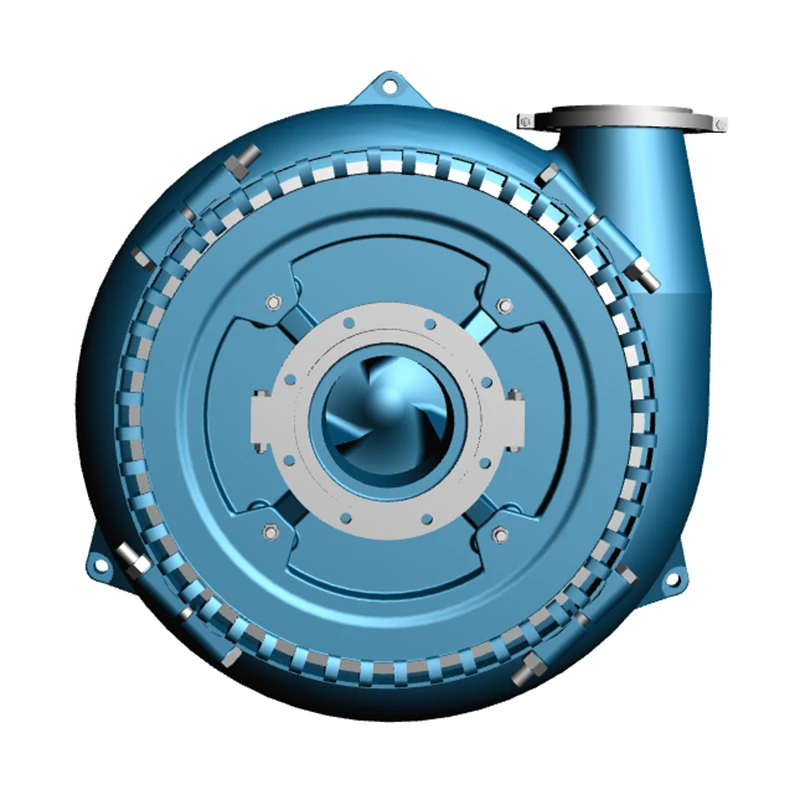

Innovative Impeller and Flow Channel Design

CNSME’s gravel pump feature a state-of-the-art impeller design that delivers maximum suction and efficient handling of large volumes of sand and gravel. The wide flow channels are engineered to minimize clogging and maintain a steady, high-capacity throughput. This innovation is crucial for applications where the material being transported contains a mix of particle sizes, as it ensures smooth operation and reduces the risk of blockages that can halt production.

Customization for Project-Specific Demands

Recognizing that every project has unique requirements, CNSME offers extensive customization options for its gravel pumps. From various sizes and power ratings to different shaft seal types and lining materials, each pump can be tailored to fit specific operational needs. This flexibility ensures that clients in construction, mining, and dredging receive equipment that is perfectly suited to their application, optimizing both performance and cost-effectiveness.

User-Friendly Controls and Safety Features

Modern CNSME gravel pumps are equipped with intuitive control panels that simplify operation and monitoring. Adjustable settings allow operators to fine-tune flow rates and pressures to match the demands of each task. Safety is also a top priority, with features such as overheat protection, automatic shutdown, and emergency stop systems built into the pumps. These enhancements not only protect the equipment but also safeguard personnel, making CNSME pumps a reliable choice for high-stakes industrial environments.

Proven Performance and Industry Trust

CNSME’s commitment to innovation and quality has earned the company a strong reputation in the global market. Their gravel pumps are trusted by operators in some of the world’s most challenging environments, from river dredging and land reclamation to mineral processing and large-scale construction projects. The combination of robust engineering, advanced features, and responsive customer support ensures that CNSME pumps consistently deliver reliable results, making them a preferred partner for those seeking efficient and modern solutions in material handling and dredging, especially for users interested in construction equipment and gravel pumps for large-scale projects.

0sem comentários ainda

Por favor digite as duas palavras abaixo