CNSME Pump: Custom Sand Gravel Pump Designs for Every Application

June 11, 2025 4:38 - no comments yetIn the fast-evolving industries such as mining, dredging, and construction, the demand for specialized equipment that can adapt to diverse operational needs is greater than ever. CNSME Pump distinguishes itself by offering custom sand gravel pump solutions tailored precisely to each application. Recognizing that no two projects are alike, the company’s approach focuses on developing pumps that are designed from the ground up to meet precise operational parameters, ensuring maximum efficiency, durability, and cost-effectiveness. Their customized pump designs help clients overcome unique challenges, making CNSME a leader in providing flexible, high-performance solutions worldwide.

Building for Tough Conditions with Tailored Materials

One of the key aspects of CNSME’s custom pump designs is the meticulous selection of materials tailored to the specific conditions of the application. Industries dealing with heavy abrasive materials require pumps made from high-quality wear-resistant alloys like high-chrome, rubber-lined liners, or wear plates that are selected based on the abrasive level of the slurry. CNSME works closely with clients to understand their operational environment and then recommends the best combination of materials to maximize lifespan. The use of custom alloys, combined with advanced manufacturing techniques, ensures that each pump can withstand the wear and tear associated with handling challenging materials, reducing downtime, and increasing productivity.

Perfecting Hydraulic Configuration for Optimal Performance

Hydraulic design is at the core of creating a custom sand gravel pump that fits specific operational needs. CNSME’s team of hydraulic engineers collaborates with clients to analyze flow regimes, slurry compositions, and pumping distances. This detailed assessment influences the design of impeller profiles, casing shapes, and liner configurations tailored to deliver the desired flow rate and pressure. By customizing the hydraulic setup, CNSME can develop pumps that maximize throughput while reducing energy consumption, thus offering a more sustainable and economical solution. Their ability to fine-tune hydraulic parameters makes each pump unique and better suited to its particular application, whether it’s high-volume dredging or precise slurry transfer.

Designing for Flexibility Across Applications

CNSME’s strength lies in the versatility of their custom designs, which span a broad spectrum of use cases. Whether a project involves sand extraction, gravel dredging, tailings pumping, or long-distance slurry transportation, CNSME can engineer a pump tailored to meet those specific needs. Customization extends beyond materials and hydraulic configuration; it also includes adjustable impeller sizes, inlet and outlet configurations, and optional auxiliary equipment such as agitation systems or high-pressure seals. This level of flexibility ensures that clients have a solution that seamlessly integrates into their existing operations, providing reliable performance across diverse environments and application demands.

Simplifying Maintenance with Custom Features

Heavy-duty applications often involve complex operations that, if disrupted by maintenance issues, can lead to significant delays and costs. CNSME’s custom pump designs are also focused on ease of maintenance. They incorporate features such as quick-change liners, removable wear plates, and accessible bearing assemblies, all chosen to facilitate simplified servicing. The custom configuration considers the specific operational cycle, allowing technicians to perform repairs quickly without extensive disassembly. This not only minimizes downtime but also enhances operational safety. For industries where uptime is critical, these tailored design features provide a competitive advantage, keeping workflows uninterrupted and costs under control.

Ensuring Safety and Environmental Compatibility

Incorporating safety and environmental standards into custom pump designs is a priority for CNSME. Each pump is engineered with features that maintain operator safety, such as pressure relief valves, vibration damping, and secure sealing systems that prevent slurry leakage. For environmentally sensitive applications, the company emphasizes designing pumps that operate efficiently to reduce power consumption and emissions. They also consider environmental protection by minimizing spill and leak risks, which are crucial in maintaining compliance with strict regulatory requirements. Tailoring these safety and eco-friendly features to specific project needs highlights CNSME’s commitment to responsible engineering and sustainable industry practices.

A Collaborative Approach with Clients

What sets CNSME apart as a custom pump manufacturer is their collaborative approach to design. They believe in working closely with each client from initial consultation through to final testing and commissioning. This process involves understanding the unique challenges faced by the operation, reviewing site conditions, and refining design specifications based on real-world data. CNSME’s engineers provide ongoing support during installation and commissioning, ensuring the custom pump functions precisely as intended. This partnership ethos builds long-term relationships, allowing clients to benefit from innovative solutions that are truly tailored to their operational needs, ultimately boosting efficiency and long-term success.

Leading Innovation for Future Needs

CNSME’s dedication to innovation is evident in their continuous investment in R&D, enabling them to develop increasingly sophisticated custom solutions. They leverage the latest technology—such as advanced computer modeling, high-performance materials, and precision manufacturing—to push the boundaries of what custom sand gravel pumps can achieve. This forward-looking approach ensures that their clients stay ahead of industry trends, with equipment designed not just for today’s needs but also adaptable for future advancements.

CNSME Pump: Innovative Features in Modern Gravel Pump Design

June 11, 2025 3:50 - no comments yetCNSME has set a new standard in gravel pump manufacturing by prioritizing the use of high chrome alloys and wear-resistant rubber throughout their product lines. These materials are chosen specifically to combat the intense abrasion and corrosion that occur during the transport of sand, gravel, and slurry. The result is a pump that not only lasts longer but also maintains high efficiency over its operational life, reducing both maintenance frequency and replacement costs for operators in construction, mining, and dredging industries.

Precision Manufacturing with Cutting-Edge Technology

To ensure each pump meets the rigorous demands of modern applications, CNSME has invested in imported advanced machinery and optimized production processes. This precision manufacturing approach guarantees that every component is built to exacting standards, resulting in pumps that deliver consistent performance even under severe duty conditions. The attention to detail in production also allows for tighter tolerances, which improves hydraulic efficiency and reduces the risk of leaks or premature wear.

Real-Time Monitoring and Data-Logging

One of the most forward-thinking features in CNSME’s modern gravel pump design is the integration of real-time monitoring and data-logging systems. Operators can now track pump performance, flow rates, and wear patterns as the equipment runs. This capability enables predictive maintenance, allowing issues to be addressed before they become critical failures. The result is less unplanned downtime, more efficient operations, and a longer lifespan for each pump, which is especially valuable for large-scale dredging and material handling projects.

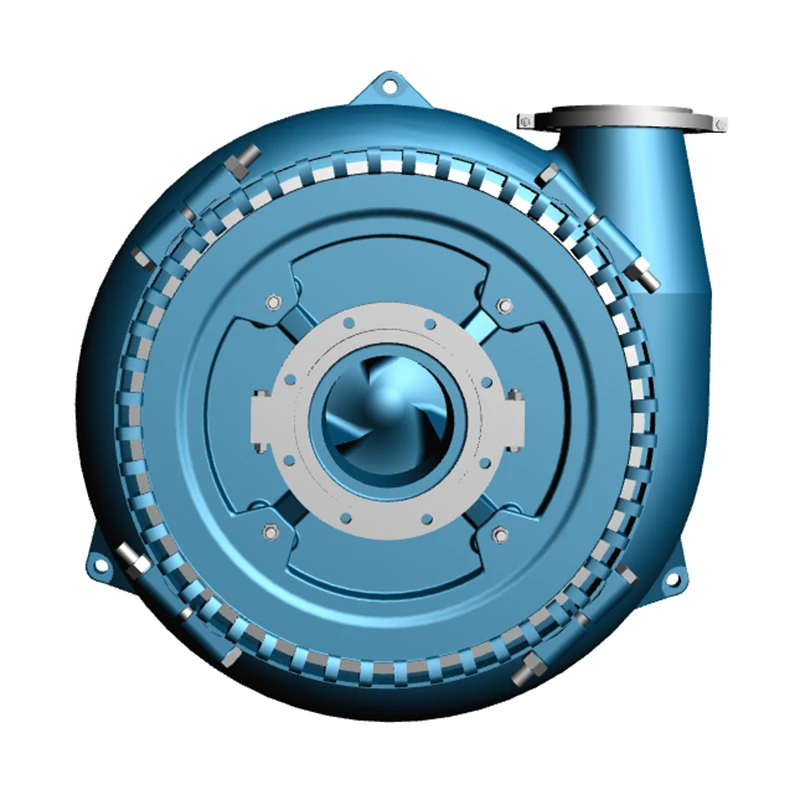

Innovative Impeller and Flow Channel Design

CNSME’s gravel pump feature a state-of-the-art impeller design that delivers maximum suction and efficient handling of large volumes of sand and gravel. The wide flow channels are engineered to minimize clogging and maintain a steady, high-capacity throughput. This innovation is crucial for applications where the material being transported contains a mix of particle sizes, as it ensures smooth operation and reduces the risk of blockages that can halt production.

Customization for Project-Specific Demands

Recognizing that every project has unique requirements, CNSME offers extensive customization options for its gravel pumps. From various sizes and power ratings to different shaft seal types and lining materials, each pump can be tailored to fit specific operational needs. This flexibility ensures that clients in construction, mining, and dredging receive equipment that is perfectly suited to their application, optimizing both performance and cost-effectiveness.

User-Friendly Controls and Safety Features

Modern CNSME gravel pumps are equipped with intuitive control panels that simplify operation and monitoring. Adjustable settings allow operators to fine-tune flow rates and pressures to match the demands of each task. Safety is also a top priority, with features such as overheat protection, automatic shutdown, and emergency stop systems built into the pumps. These enhancements not only protect the equipment but also safeguard personnel, making CNSME pumps a reliable choice for high-stakes industrial environments.

Proven Performance and Industry Trust

CNSME’s commitment to innovation and quality has earned the company a strong reputation in the global market. Their gravel pumps are trusted by operators in some of the world’s most challenging environments, from river dredging and land reclamation to mineral processing and large-scale construction projects. The combination of robust engineering, advanced features, and responsive customer support ensures that CNSME pumps consistently deliver reliable results, making them a preferred partner for those seeking efficient and modern solutions in material handling and dredging, especially for users interested in construction equipment and gravel pumps for large-scale projects.

Why Leading Brands Trust HARDVOGUE for IML Film Manufacturing

June 11, 2025 1:24 - no comments yetIn today’s highly competitive marketplace, brands are constantly seeking ways to distinguish their products through innovative, high-quality packaging. One of the most critical aspects of this strategy is ensuring that packaging materials not only look appealing but also perform reliably under various conditions. HARDVOGUE has established itself as a trusted partner for leading brands worldwide in the manufacturing of IML (In-Mold Labeling) films. Their commitment to quality, technological excellence, and sustainable practices has earned them the confidence of top brands across diverse industries, from cosmetics to food packaging and beyond. This trust is built on a foundation of innovative solutions, consistent quality, and a true understanding of client needs.

Unmatched Quality and Consistency

Leading brands prioritize reliability, and HARDVOGUE’s reputation is built on manufacturing IML films of unparalleled quality. Every batch undergoes rigorous quality control processes to ensure superior print clarity, color consistency, and surface durability. This level of precision is vital for brands aiming to communicate their identity through vibrant visuals and complex graphics. The company’s advanced manufacturing facilities leverage state-of-the-art equipment, which guarantees uniform thickness, adhesion strength, and resistance to scratching and environmental factors. Such consistency ensures that regardless of production scale or geographic location, brands receive the same high-grade product, maintaining their brand image at every point of the supply chain.

Cutting-Edge Technology and Innovation

HARDVOGUE's leadership in the industry can be attributed to their continuous investment in technological innovation. They employ the latest in material science and printing technology, supporting high-resolution graphics, metallic effects, holographics, and textured finishes. Their ability to customize films according to specific client requirements—whether it’s flexibility for intricate molds or eco-friendly formulations—sets them apart. Their R&D teams work tirelessly to develop new formulations that enhance performance, such as improved adhesion, oil and temperature resistance, and recyclability. This relentless pursuit of innovation reassures brands that they are partnering with a manufacturer capable of evolving alongside industry trends, ensuring their packaging remains cutting-edge.

Commitment to Sustainability

In an era where environmental responsibility influences purchasing decisions, brands are increasingly demanding sustainable packaging options. HARDVOGUE has responded by integrating eco-friendly practices into their manufacturing processes. They offer recyclable IML Film made from biodegradable or bio-based polymers, aligning with global efforts to reduce plastic waste. Their environmentally conscious approach extends to reducing material use through thinner film designs without compromising durability, as well as supporting water-based and low VOC inks to minimize pollution. Leading brands trust HARDVOGUE not only for their performance but also for their dedication to creating solutions that help mitigate the environmental impact, making sustainability an integral part of their manufacturing ethos.

Tailored Solutions for Diverse Industry Needs

Any successful partnership relies on responsiveness and customization, and HARDVOGUE excels in providing tailored solutions that meet the specific requirements of different industries. Whether it’s food packaging requiring oil resistance and microwave stability, cosmetics demanding vibrant aesthetics and high scratch resistance, or automotive interiors needing durability and luxury finishes, HARDVOGUE crafts films that perform perfectly. They work closely with clients from conceptualization through production, ensuring that each film aligns with the unique specifications—be it in texture, thickness, or visual effect. This flexibility in manufacturing processes makes them the go-to partner for brands seeking bespoke packaging solutions that enhance consumer appeal.

Consistent Supply Chain Excellence

Global brands operate under tight schedules and high volume demands, making reliable supply chains a non-negotiable aspect of their operations. HARDVOGUE’s extensive manufacturing capacity and strategic global locations enable them to fulfill large and complex orders promptly and efficiently. Their integrated supply chain management ensures just-in-time delivery and consistent product availability. Moreover, their proactive communication and logistics planning mitigate potential disruptions, ensuring brands can meet their distribution deadlines without compromise. This dependability transforms HARDVOGUE from just a supplier into a strategic partner that supports the entire product lifecycle.

Partnership and Customer-Centric Approach

Beyond producing high-quality films, HARDVOGUE’s true strength lies in forging long-term relationships with their clients. Their customer-centric approach involves collaborative development, technical support, and ongoing innovation that adapts to evolving market demands. Industry-leading brands trust HARDVOGUE because they know they will receive expert guidance, tailored solutions, and proactive problem-solving. They view client success as their success and invest in understanding each brand’s unique goals, challenges, and future plans. This dedication to partnership fosters loyalty and mutual growth, positioning HARDVOGUE as a trusted innovator in the highly demanding world of IML film manufacturing.

Conclusion: A Proven Track Record of Excellence

Leading brands across the globe continue to place their trust in HARDVOGUE because of their unwavering commitment to quality, innovation, and sustainability. Their ability to develop customized, high-performing IML films that meet the strictest industry standards makes them a valued partner for brands looking to push the boundaries of packaging design

The Importance of Quality Control at These HARDVOGUE Packaging Material Manufacturer

June 10, 2025 2:24 - no comments yetIn the competitive landscape of packaging material manufacturer, maintaining consistent quality is not just a goal; it is a fundamental necessity. HARDVOGUE recognizes that quality control is the backbone of its reputation and long-term success. Delivering reliable, safe, and visually appealing packaging solutions requires rigorous oversight throughout every stage of production. This commitment to quality control ensures that clients receive products that meet the highest standards, align with industry regulations, and fulfill their brand promises. By emphasizing quality management, HARDVOGUE not only builds trust with its customers but also sets a benchmark for excellence within the industry.

The Role of Precision in Material Selection and Raw Material Inspection

From the very beginning of its production process, HARDVOGUE understands that the foundation of quality lies in selecting the right raw materials. The company conducts meticulous inspections of incoming raw materials to verify their purity, strength, and compliance with safety standards. This step is crucial because the properties of raw materials directly influence the durability, appearance, and functionality of the final product. Whether it’s paper, plastic, or coated films, each raw material is subject to specific testing procedures that detect impurities, inconsistencies, or deviations from specified standards. High-quality raw materials pave the way for premium finished products, making precise inspection an indispensable part of HARDVOGUE’s overall quality control system.

Continuous Monitoring during Manufacturing Processes

Quality control at HARDVOGUE doesn’t stop once raw materials are approved; it extends deeply into the manufacturing processes. The company employs advanced monitoring systems and real-time inspections to ensure that every batch adheres to strict specifications. Automated sensors track parameters such as temperature, humidity, and machine calibration to prevent variances. Skilled operators routinely check for defects like uneven coating, printing flaws, or misalignments. This continuous monitoring helps catch issues early, reducing waste and preventing substandard products from reaching clients. It not only sustains high standards but also optimizes efficiency, ensuring that production runs smoothly without sacrificing quality.

Rigorous Testing and Quality Assurance of Finished Products

Once manufacturing is complete, HARDVOGUE subjects its packaging materials to comprehensive testing protocols. These include tensile strength tests, tear resistance, barrier performance measurement, and visual inspections for defects such as bubbles or scratches. The company places a strong emphasis on meeting international standards, often seeking certifications such as ISO or food safety standards depending on the application. Such rigorous testing guarantees that each product can withstand handling, transportation, and storage stresses. It also ensures the packaging performs its primary functions—protecting, preserving, and presenting products—without failure. Consistent quality assurance builds trust with clients, reinforcing HARDVOGUE’s reputation as a dependable partner.

The Impact of Quality Control on Customer Satisfaction and Brand Reputation

Reliable quality control directly influences customer satisfaction, which is critical for maintaining long-term relationships and brand loyalty. When clients receive packaging materials that are flawless and perform as expected, their confidence in HARDVOGUE grows. Conversely, discovering defects or inconsistencies can damage a client’s brand image, especially if the packaging fails during transit or storage. As a result, HARDVOGUE’s stringent quality control measures serve as a safeguard, ensuring that every product leaving the facility upholds the company’s reputation for excellence. High-quality packaging not only enhances the consumer experience but also affirms the manufacturer’s commitment to delivering value and reliability.

Adapting Quality Control for Innovation and Sustainability

As the packaging industry evolves, embracing innovation and sustainability becomes integral to maintaining high standards. HARDVOGUE’s quality control processes are adaptable, incorporating new testing methods for eco-friendly materials and cutting-edge design features. For example, when developing biodegradable films or recyclable cartons, the company rigorously assesses their performance in real-world conditions to ensure they meet durability and safety benchmarks. This proactive approach to quality management ensures that even innovative solutions adhere to strict criteria without compromising environmental goals. It demonstrates that maintaining high standards is compatible with the industry’s push toward more sustainable practices, further strengthening HARDVOGUE’s leadership role.

Conclusion: Commitment to Excellence and Industry Leadership

At the core of HARDVOGUE’s success as a packaging material manufacturer lies its unwavering dedication to quality control. Implementing comprehensive procedures—from raw material inspection and process monitoring to final product testing—ensures excellence at every step. This unwavering focus not only guarantees customer satisfaction but also upholds the company’s reputation for reliability and innovation. As the industry faces new challenges and demands, HARDVOGUE’s robust quality management systems enable it to maintain high standards while embracing innovation and sustainability. Ultimately, the importance of quality control at HARDVOGUE goes beyond compliance; it embodies a company’s commitment to serving clients with premium, dependable packaging solutions that support their growth and success.

The Importance of Quality Control at HARDVOGUE Packaging Material Manufacturer

June 10, 2025 2:13 - no comments yetIn the competitive landscape of packaging material manufacturing, maintaining consistent quality is not just a goal; it is a fundamental necessity. HARDVOGUE recognizes that quality control is the backbone of its reputation and long-term success. Delivering reliable, safe, and visually appealing packaging solutions requires rigorous oversight throughout every stage of production. This commitment to quality control ensures that clients receive products that meet the highest standards, align with industry regulations, and fulfill their brand promises. By emphasizing quality management, HARDVOGUE not only builds trust with its customers but also sets a benchmark for excellence within the industry.

The Role of Precision in Material Selection and Raw Material Inspection

From the very beginning of its production process, HARDVOGUE understands that the foundation of quality lies in selecting the right raw materials. The company conducts meticulous inspections of incoming raw materials to verify their purity, strength, and compliance with safety standards. This step is crucial because the properties of raw materials directly influence the durability, appearance, and functionality of the final product. Whether it’s paper, plastic, or coated films, each raw material is subject to specific testing procedures that detect impurities, inconsistencies, or deviations from specified standards. High-quality raw materials pave the way for premium finished products, making precise inspection an indispensable part of HARDVOGUE’s overall quality control system.

Continuous Monitoring during Manufacturing Processes

Quality control at HARDVOGUE doesn’t stop once raw materials are approved; it extends deeply into the manufacturing processes. The company employs advanced monitoring systems and real-time inspections to ensure that every batch adheres to strict specifications. Automated sensors track parameters such as temperature, humidity, and machine calibration to prevent variances. Skilled operators routinely check for defects like uneven coating, printing flaws, or misalignments. This continuous monitoring helps catch issues early, reducing waste and preventing substandard products from reaching clients. It not only sustains high standards but also optimizes efficiency, ensuring that production runs smoothly without sacrificing quality.

Rigorous Testing and Quality Assurance of Finished Products

Once manufacturing is complete, HARDVOGUE subjects its packaging materials to comprehensive testing protocols. These include tensile strength tests, tear resistance, barrier performance measurement, and visual inspections for defects such as bubbles or scratches. The company places a strong emphasis on meeting international standards, often seeking certifications such as ISO or food safety standards depending on the application. Such rigorous testing guarantees that each product can withstand handling, transportation, and storage stresses. It also ensures the packaging performs its primary functions—protecting, preserving, and presenting products—without failure. Consistent quality assurance builds trust with clients, reinforcing HARDVOGUE’s reputation as a dependable partner.

The Impact of Quality Control on Customer Satisfaction and Brand Reputation

Reliable quality control directly influences customer satisfaction, which is critical for maintaining long-term relationships and brand loyalty. When clients receive packaging materials that are flawless and perform as expected, their confidence in HARDVOGUE grows. Conversely, discovering defects or inconsistencies can damage a client’s brand image, especially if the packaging fails during transit or storage. As a result, HARDVOGUE’s stringent quality control measures serve as a safeguard, ensuring that every product leaving the facility upholds the company’s reputation for excellence. High-quality packaging not only enhances the consumer experience but also affirms the manufacturer’s commitment to delivering value and reliability.

Adapting Quality Control for Innovation and Sustainability

As the packaging industry evolves, embracing innovation and sustainability becomes integral to maintaining high standards. HARDVOGUE’s quality control processes are adaptable, incorporating new testing methods for eco-friendly materials and cutting-edge design features. For example, when developing biodegradable films or recyclable cartons, the company rigorously assesses their performance in real-world conditions to ensure they meet durability and safety benchmarks. This proactive approach to quality management ensures that even innovative solutions adhere to strict criteria without compromising environmental goals. It demonstrates that maintaining high standards is compatible with the industry’s push toward more sustainable practices, further strengthening HARDVOGUE’s leadership role.

Conclusion: Commitment to Excellence and Industry Leadership

At the core of HARDVOGUE’s success as a packaging material manufacturer lies its unwavering dedication to quality control. Implementing comprehensive procedures—from raw material inspection and process monitoring to final product testing—ensures excellence at every step. This unwavering focus not only guarantees customer satisfaction but also upholds the company’s reputation for reliability and innovation. As the industry faces new challenges and demands, HARDVOGUE’s robust quality management systems enable it to maintain high standards while embracing innovation and sustainability. Ultimately, the importance of quality control at HARDVOGUE goes beyond compliance; it embodies a company’s commitment to serving clients with premium, dependable packaging solutions that support their growth and success.