Die casting Malaysia is now a crucial part of the country's manufacturing industry that contributes significantly to industries like aerospace, automotive, electronics, and consumer goods. The process involves injecting molten metal into a mold under high pressure to create precisely-crafted and complex components, with little requirement to process them post-production. The Malaysian manufacturing landscape has evolved quickly, as companies invest in the latest technology to improve the effectiveness and quality of die-cast products. This has meant that the industry has become an integral part of the supply chain of global importance offering high-quality metal products for international markets. Initiatives by the government to encourage industrial growth and technological advancements has further strengthened the position of Malaysia as a major die-casting center within Southeast Asia. With skilled workforce strong infrastructure, as well as strategic location has made Malaysia an ideal location for companies seeking to invest in die-casting manufacturing.

The automobile industry is among of the biggest consumers of die-cast parts in Malaysia, with manufacturers relying on the process to produce robust and lightweight parts. Die-cast parts made of zinc and aluminum are extensively used in automobile production due to their strength in addition to their low weight and resistant to corrosion. Engine components, transmission housings, brackets, and structural parts are among die-cast components that improve the performance and effectiveness of contemporary vehicles. Because of Malaysia being the home of some significant automotive companies and suppliers, the local die-casting sector has seen a rise in demand for precision-engineered metal parts. Many die-casting companies have invested in advanced machines and automated equipment to meet the strict quality standards of the automotive industry. As electric vehicles gain popularity and the market is developing special die-cast parts for battery casings, motor housings and light structural elements.

Die casting is also essential in the electronics and telecom industries in Malaysia in which precision and dependability are crucial. The country is a major exporter of electronic parts, offering global brands high-end metal enclosures, heat sinks and connectors. Die casting's ability to make complex forms with tight tolerances makes it ideal for manufacturing these components, ensuring they fit seamlessly into various electronic gadgets. A lot of Malaysian die-casting firms work with technology firms to develop customized solutions for laptops, smartphones Data centers, laptops, as well as telecommunications equipment. With the continued growth of the digital economy, demand for die-casting components that are advanced will likely to increase. The companies are working on improving thermal conductivity, electrical shielding, and lightweight properties to improve the performance of electronic devices. Automation and advanced manufacturing methods will further boost effectiveness in the manufacture of high-precision metal parts.

Sustainability has been a key aspect of Malaysia's die-casting business as companies have been implementing sustainable manufacturing methods. Reuse and recycling of metal materials, particularly zinc and aluminum have become common practices in die casting, reducing waste and conserving resources. Many manufacturers have also adopted efficient casting and melting techniques that use less energy to reduce carbon emissions as well as overall energy consumption. This shift to green manufacturing has led manufacturers to investigate greener casting methods such as low-pressure die casting and gravity die casting, which produce high-quality parts with minimal production waste. Surface treatments and coatings that increase the durability and resistance of die-cast components are also being developed with eco-friendly substances. With industries around the world pushing towards greener supply chains Malaysian die-casting businesses are positioning themselves as leaders in the field of sustainable metal casting ensuring long-term competitiveness in the world market. To acquire added information kindly visit

www.senadiecasting.com.my/

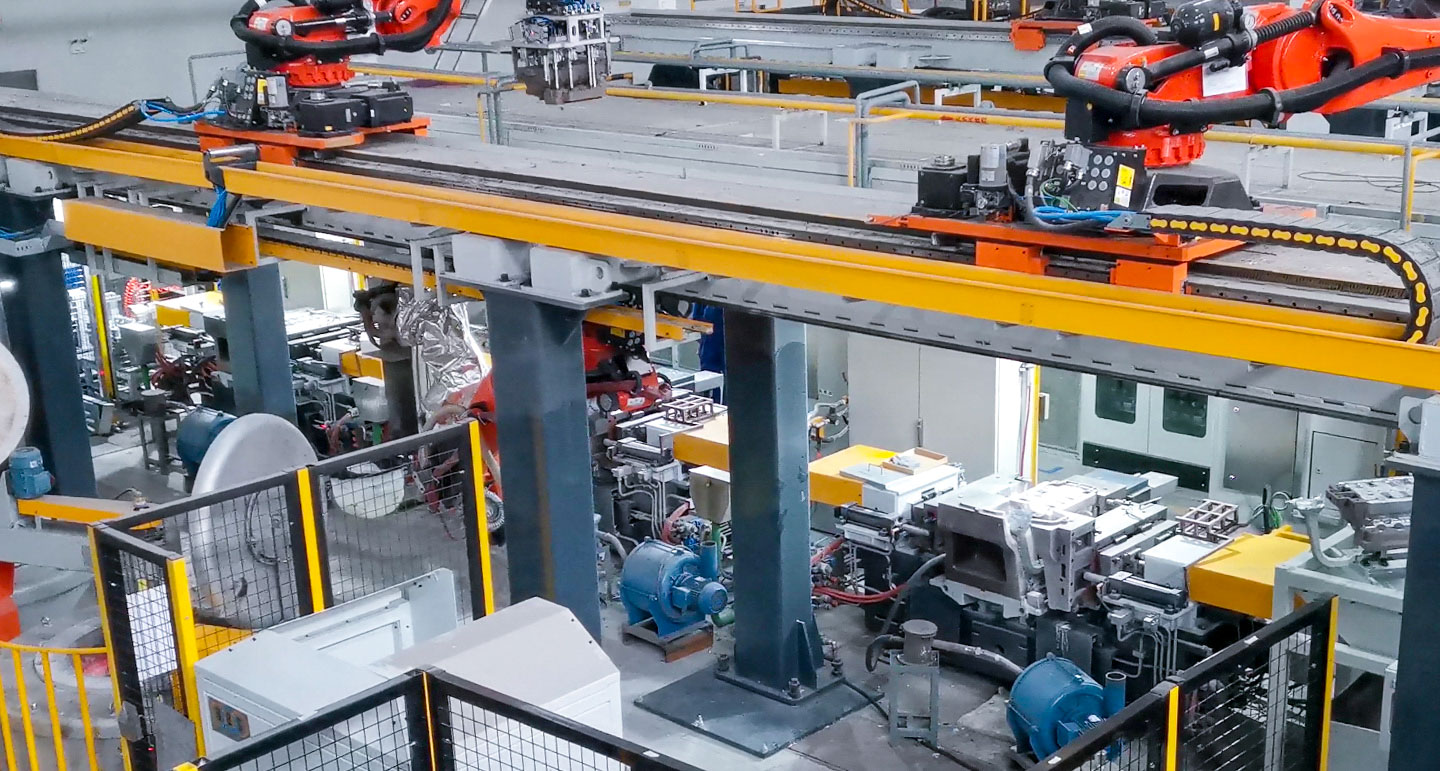

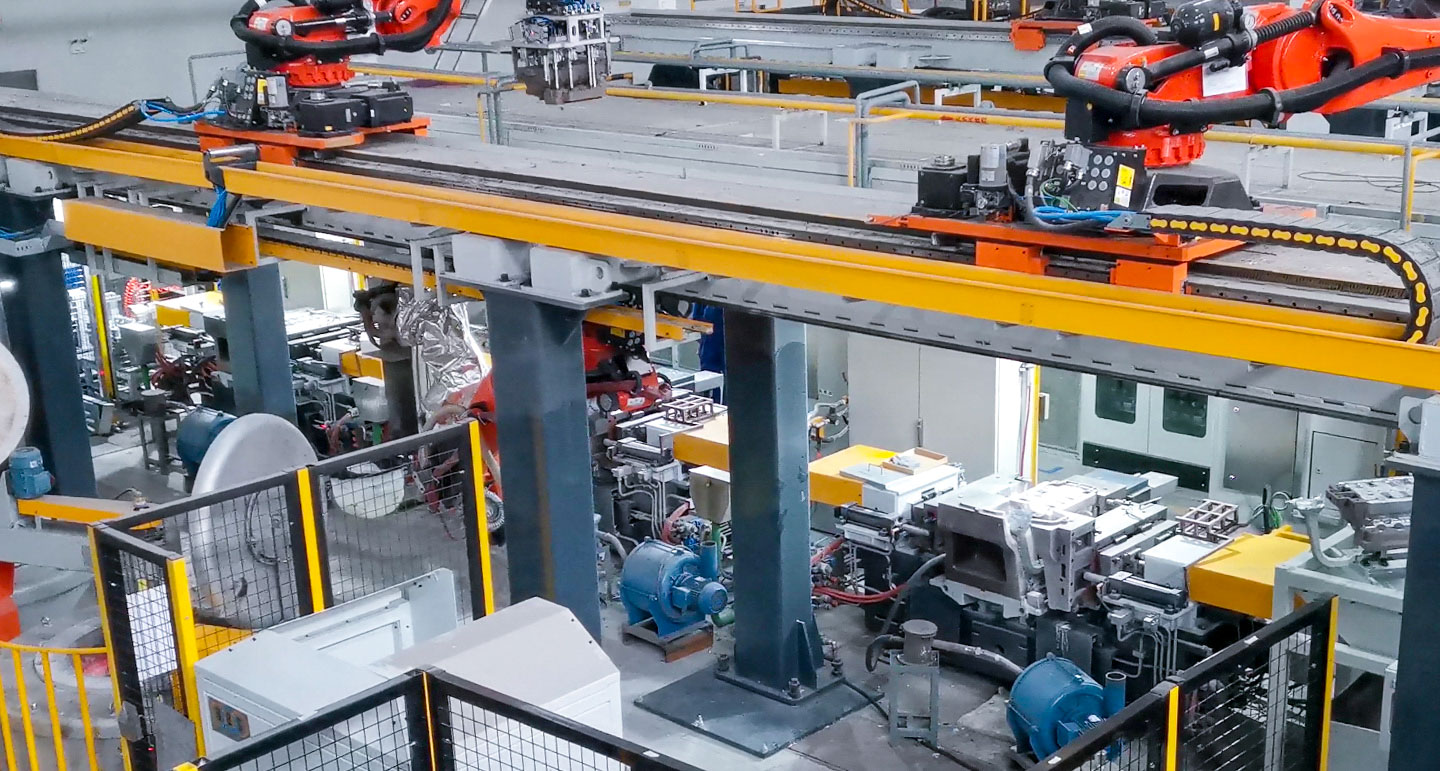

Utilizing cutting-edge technology has played an essential part in the development of Malaysia's die casting industry, allowing manufacturers to improve the quality, efficiency and scalability. The use of computer-aided designing and simulation software permits companies to optimize mold designs which reduces production mistakes and the waste of materials. Automatization and robotics for die-casting is boosting productivity, while also ensuring consistent quality in large-scale manufacturing. Industry 4.0 technology, like continuous data monitoring, Internet of Things , and artificial intelligence are improving process control as well as proactive maintenance. These advancements aid in helping Malaysian companies that use die casting keep their competitive edge in an ever digitalized manufacturing landscape. Through continuous investment in research and development, Malaysia is strengthening its image as a manufacturing center that is able to meet the requirements of precise engineering across a range of industries.

Die-casting in Malaysia is set to grow in the long run as demand for premium metal parts continues to grow. The country's strategic location as well as its skilled workforce and strong commitment to technological advancement has made it a leading manufacturing hub throughout the region. Businesses that adopt automation, artificial intelligence, and data-driven manufacturing processes will gain a competitive advantage that will ensure efficiency and excellence. Due to increasing use in the electronics, automotive, and aerospace industries Die-casting firms operating in Malaysia have the opportunity to increase their capabilities as well as strengthen their international presence. As sustainability becomes a key priority, those who adopt sustainable practices and use energy efficient techniques will have a better chance of achieving the future. The evolution of the die-casting business in Malaysia reflects the country's dedication to precision manufacturing, technological innovation, and economic progress, solidifying its role as an international pioneer in the field of metal casting.

0sem comentários ainda